Fuel costs are a relatively large part of the daily work of concrete pump trucks. If investors want to reduce pumping costs, they must consider how to make concrete pump trucks more fuel-efficient. In fact, engineering vehicles such as concrete boom pumps and concrete mixer trucks have some fuel-saving tips just like ordinary trucks.

Generally speaking, experienced drivers are more fuel-efficient than novice drivers. For concrete pump trucks, what are the specific fuel-saving tips?

1.Choose the right lubricating oil

Choosing the right lubricating oil is a key factor for the engine of the concrete pump truck to reduce power consumption and fuel consumption. In order to reduce fuel consumption, lubricating oils of different specifications and models should be selected in different seasons in areas with obvious seasonal changes and large temperature changes.

2.Keep the appropriate speed

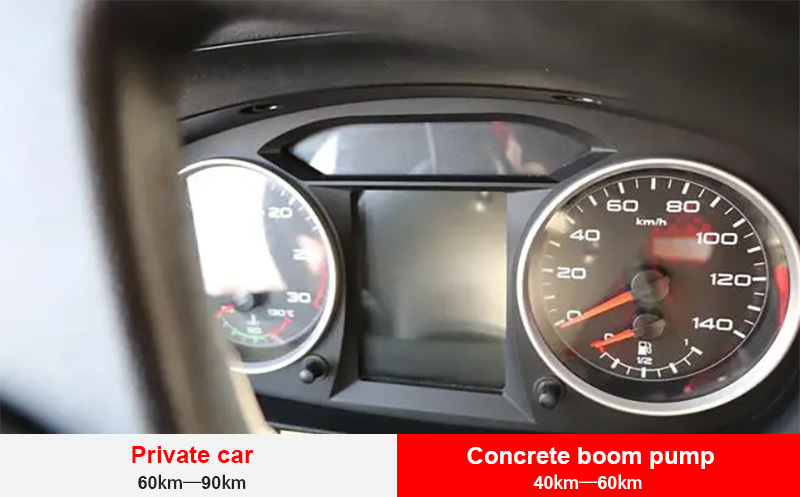

The appropriate speed actually refers to the economic speed. The so-called economic speed is the speed at which the car consumes the least fuel during the driving process. Generally speaking, the economic speed has a limited range. Taking a private car as an example, its economic speed is 60 to 90 kilometers per hour. In this speed range, the fuel consumption is relatively low. When the vehicle speed is higher, the resistance of the vehicle to the wind will be greater, which will increase fuel consumption.

For concrete pump trucks, the fuel consumption is the most economical when the speed is in the range of 40 to 60 kilometers per hour.

In the case of high speed driving, the higher the gear, the more fuel efficient. In the daily driving process, it is necessary to choose a gear that matches the speed of the vehicle. When pumping concrete, you should choose a high gear with a small transmission ratio. At this time, the thermal efficiency of the engine of the concrete boom pump is the highest, which also means more fuel consumption.

3.Check the tire pressure of the chassis

Anyone who drives frequently knows that if the tire pressure is too low, it will increase fuel consumption. This is because the tire pressure is too low, the tire is prone to deformation, which increases the contact area with the ground and increases the friction. To overcome friction, the engine has to do more work.

Therefore, the tire pressure of the chassis tires of the concrete pump truck should be kept at the value set by the concrete pump manufacturer. So it is necessary to check the tire pressure of the tire regularly.

In addition, different road conditions have different requirements for tire pressure. When driving on asphalt or concrete roads, just set the normal tire pressure. If you are going to drive on sandy or muddy roads, it is beneficial to set the tire pressure slightly lower.

4.Reduce the weight of vehicle

Under the same chassis and engine conditions, except the chassis, the lighter the concrete pump truck, the more fuel-efficient it will be. On the contrary, if the weight of the vehicle itself is increased, the fuel consumption will be increased accordingly. Therefore, during construction, unnecessary additional equipment on truck-mounted concrete pump should be removed without affecting the quality of the project.

Some people will put unnecessary accessories or sundries on the truck-mounted concrete pump, which will undoubtedly increase the weight of the concrete pump truck. Although the impact of increased weight on fuel consumption cannot be immediately shown, fuel consumption will definitely increase over time. Therefore, the unnecessary sundries on the concrete pump truck should be removed in time.

Another factor that may increase the weight of the pump truck is the pump pipe. For a 49m pump truck, there are about 40 or 50 straight and bent pipes of different sizes. Some manufacturers on the market produce inferior pump pipes that are very unwearable, but they can only increase the thickness of the pump pipe in order for it to reach the established service life.

This greatly increases the weight of the pump pipe, but also increases the fuel consumption and boom load. Therefore, the heavier the pump pipe is not the better, and inferior pump pipe should not be used firmly.

5.Keep good driving habits

As the pump truck accelerates, the engine needs to increase its power, and each time the brakes are applied, the energy from that power is dissipated with heat. Also, both sudden acceleration and the use of higher engine speeds will cause the engine to consume more fuel.

Therefore, the driver should not accelerate suddenly or brake suddenly during the daily driving of the pump truck. Both of these situations will increase the fuel consumption of the concrete pump truck. The correct driving method should be to start in a low gear. During driving, pay attention to the matching of vehicle speed and gear.

6.Pay attention to high and low pressure pumping in different situations

The process of converting the kinetic energy of the engine into hydraulic energy is actually the process of converting the chemical energy of the fuel consumed by the engine into kinetic energy. Therefore, to obtain a higher pumping pressure, the engine has to do more work, which means that the engine's fuel consumption increases. So, when to use low pressure pumping? When to use high pressure pumping? Pumping concrete under different pressure conditions has a great influence on fuel consumption.

When pumping concrete horizontally or downwards, the gravitational effect of the concrete to be overcome is relatively small, so in this case, low pressure pumping of concrete is sufficient. If concrete is pumped vertically upwards, high pressure pumping is required. Therefore, it is also very helpful to skillfully deal with the switching of high and low pressure in various situations to reduce fuel consumption.

7.Regular maintenance of concrete pump truck

If a concrete pump truck is not maintained regularly, it can develop various problems, such as partially clogged filters, poor engine oil performance, etc. These problems all increase fuel consumption and increase emissions.

At the same time, pay attention to check the tire pressure to avoid insufficient air pressure, which will increase the rolling resistance between the vehicle tires and the road, thus consuming more fuel.

If you want to get more information about saving fuel consumption of concrete pump trucks, please contact us!