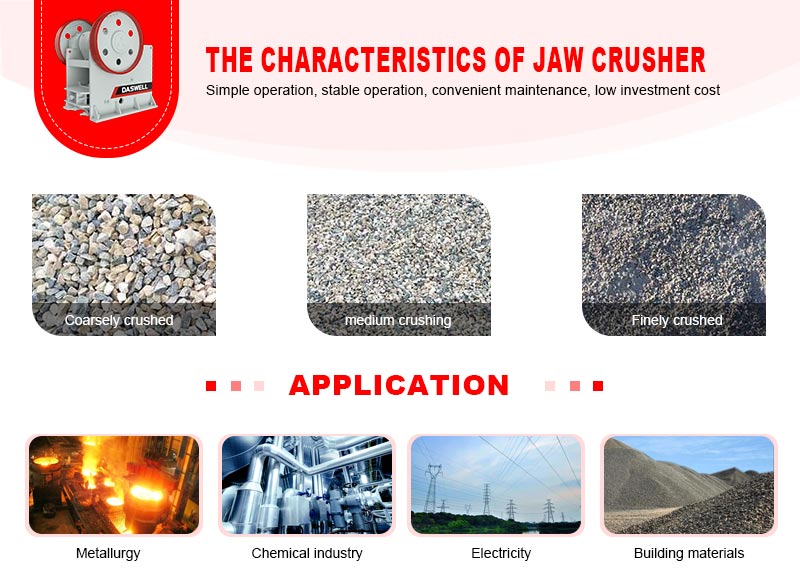

Jaw crusher is an early crushing equipment, which is welcomed by many customers because of its simple operation, stable performance, easy maintenance and low investment cost. Jaw crusher is commonly used in metallurgy, chemical, electric power, building materials and other industries for coarse, medium and fine crushing of various rocks. In addition, jaw crusher has different specifications and models to meet the needs of different customers.

After purchasing the jaw crusher, investors will think about a question, how to maximize the production capacity of the jaw crusher, so as to maximize their own interests. So, how to maximize the working efficiency of jaw crusher? There are several aspects to be noted.

The selection of materials

On the one hand, pay attention to the hardness of the material. Jaw crushers crush materials by extrusion. Generally speaking, the harder the rock, the greater the compressive strength and the harder it is to crush. On the contrary, the hardness of the rock is reduced, the production efficiency will be improved.

On the other hand, pay attention to the dryness and wetness of the material. Although the humidity of the material has little effect on the crushing efficiency, when there is a lot of mud or fine ore in the material, the fine material is easy to stick to the coarse material, which undoubtedly increases the difficulty of discharging and reduces the production efficiency. In severe cases, it will also cause blockage of the discharge port, which will affect the normal operation of the machine.

The selction of machine

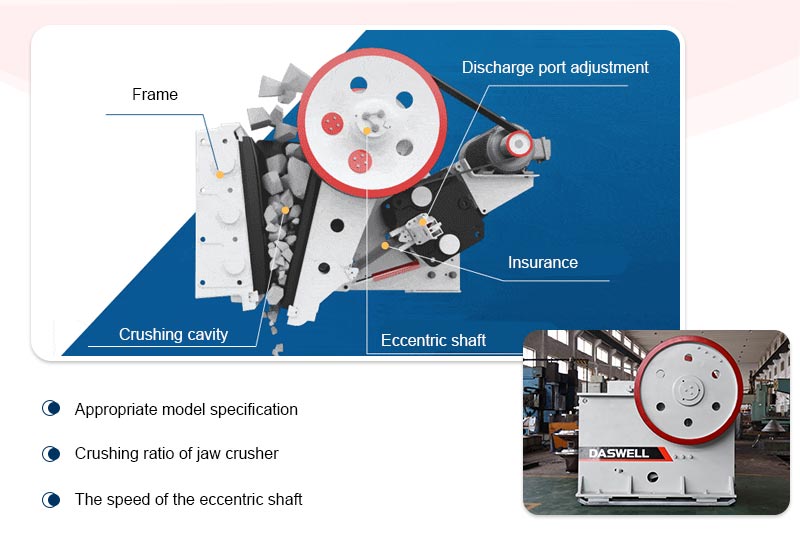

First of all, determine the model of the jaw crusher purchased. Different customers need to process different materials, and their needs must also be different, so it is necessary to choose the appropriate model and specification. For example, if you buy a PE250×400 jaw crusher, its maximum feeding size is 210mm, but you use it to process 300mm materials, which will not only affect its output, but also cause a certain degree of damage to the machine .

Then, consider the crushing ratio of the jaw crusher. Jaw crushers are generally used for crushing harder rocks. The larger the size of the crushed material, the greater the crushing ratio (the ratio of the particle size of the material before crushing to the particle size of the crushed material) that the jaw crusher needs to achieve, and the lower the production efficiency. On the contrary, the production efficiency of the jaw crusher will be improved.

Finally, consider the rotation speed of the eccentric shaft. When the eccentric shaft rotates once, the moving jaw of jaw breaker will swing back and forth once. The first half circle of the movable jaw swings to crush the material, and the second half circle unloads the material. So it is good to increase the eccentric shaft speed appropriately to improve the efficiency of material crushing. However, it should be noted that if the rotation speed of the eccentric shaft is too high, the crushed materials will not be discharged out of the discharge port in time, resulting in blockage.

Method of feeding

First of all, pay attention to the feeding size of the material. Some operators will take the size of feed inlet as the maximum feeding size, so it will lead to the material that exceeds the maximum feeding size will often block the feed inlet. Each blockage will cause the equipment to stop, seriously affecting the production efficiency of the jaw crusher. Therefore, the feeding size of the material must be strictly controlled.

Secondly, strictly control the feeding quantity. If the feeder puts too much material into the jaw crusher, the material will not be crushed in time, and the crushed material cannot be discharged in time, resulting in the phenomenon of material jam at the discharge port. Therefore, both discontinuous feeding and excessive feeding will affect the production capacity of the jaw crusher.

Then, adjust the feeding angle and feed the material evenly. Some investors will use chute unloading or dump truck to unload the material vertically. This will not only damage the equipment, but also affect the productivity of the crusher. In order to improve the performance of jaw crusher and meet its demand of even feeding, investors can equip vibrating feeder to feed the jaw crusher evenly.

Finally, adjust the nip angle of the jaw crusher (the angle between the movable jaw and the fixed jaw). The size of the discharge opening of the crusher is directly related to the nip angle and crushing ratio of the crusher. Within the allowable range, if the discharge opening is appropriately increased, the nip angle and crushing ratio will decrease, and the productivity will increase. On the contrary, if the discharge opening is reduced, the nip angle and crushing ratio will increase, and the productivity will decrease.

Method of operation

The operators of the jaw crusher must undergo professional training and have a comprehensive understanding of the performance of the equipment. Reasonable use of equipment in accordance with correct operating specifications can not only ensure your personal safety, but also improve the production efficiency of the jaw crusher.

Qualified operators should not only be familiar with the operation of the machine, but also be clear about the internal structure and working principle of the machine. When the jaw crusher has problems during the operation, the operator can find the problems and solve them in time. This can reduce the downtime of the machine and improve its production efficiency.

Daily maintenance

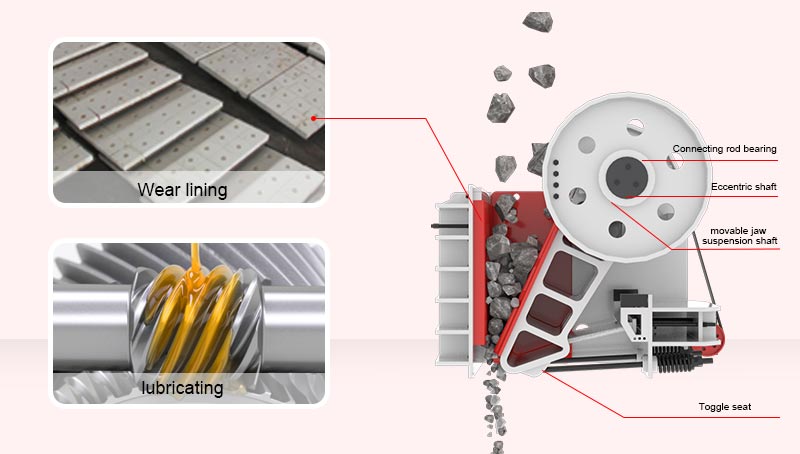

Keeping the jaw crusher in good working condition is an important prerequisite for improving its productivity. As a large crushing equipment, it works with great labor intensity, and the wear and tear of important parts will inevitably occur. Therefore, in normal use, the operator must pay attention to the maintenance of the jaw crusher, such as installing the wear-resistant liner on the surface of the jaw plate to reduce the wear of the jaw plate.

Pay attention to the lubrication of the main parts of the jaw crusher, such as the lubrication of the connecting rod bearing, eccentric shaft, movable jaw bearing, toggle plate seat and movable jaw suspension shaft of the jaw crusher, which can achieve the dual purpose of improving productivity and extending service life.

If you want to get more information about jaw crusher, please pay attention to the update of our website in time!