In recent years, the use of self loading mixer trucks has increased. Whether in cities or rural areas, it plays an important role in infrastructure construction. So why are self loading mixer trucks so popular among customers? This article will introduce you to the advantages of self loading concrete mixer trucks.

10 Reasons Why Self Loading Mixers Are Popular

Multiple functions and high production efficiency

Self loading mixer truck integrates the functions of loading, mixing, moving and unloading. It can work continuously at the construction site, which improves the production efficiency.

Save manpower and labor costs

The self loading concrete mixer only requires one operator to complete all operations, reducing the workload of manual mixing and transporting concrete, reducing the labor intensity of workers, and reducing labor costs. And fewer people need to be involved in the process of unloading concrete at the construction site.

Ensure the quality of concrete

It has mixing blades inside, which can ensure that the concrete is fully mixed to avoid uneven mixing and ensure the quality of concrete.

Moreover, the instant production of concrete ensures the freshness of the concrete. The concrete is mixed just before transportation and discharge, reducing the risk of premature hardening or loss of flowability. Concrete quality is critical to the durability of engineered structures.

Save production costs

The self loading mixer truck can not only produce concrete, but also act as a transport vehicle to deliver concrete directly to the construction site. This eliminates the need to purchase additional concrete pumps and delivery equipment, reducing production costs.

Automatic control and precise proportioning

The self-loading mixer is equipped with a precise automatic loading system. It can accurately prepare concrete according to project requirements. This ensures the precise proportions of raw materials such as cement, aggregate, sand and water in the concrete, ensuring the quality and strength of the concrete.

Strong adaptability and practicality

The self-feeding mixer can be adapted to different types of concrete projects, such as roads, bridges, buildings, etc., and has strong applicability. Moreover, it has the functions of a loader, a drum mixer and a mixer truck, and is more practical.

Save time

It can be moved during the process of mixing concrete, which reduces the time of transporting concrete from the production site to the construction site, helps improve the construction progress, and reduces the construction cycle and production costs.

Save space

The self-loading concrete truck is equivalent to a small mobile mixing plant. However, compared with the mobile mixing plant, it occupies a smaller area and does not require additional storage areas for concrete, saving space on the construction site.

On-site producing, reducing waste

The self-loading mixer truck can produce concrete on demand according to the actual needs of the construction site, avoiding the problem of excess concrete being wasted due to early production.

High safety

The self loading mixer truck has reasonable body structure and counterweight design, stable walking and high safety factor. Scientific design, articulated body, four-wheel drive, and full of power. Whether it is a flat road or a country road, the self-loading mixer truck can drive smoothly.

Even in mountainous areas, the self-loading mixer truck can adapt well. Because it uses full-time off-road four-wheel drive, it has sufficient power and strong controllability. It has strong stability when climbing in mountainous areas and can climb up to 30 degrees. Steel wire tires are wear-resistant and durable, have strong grip, and can adapt well to the slope of mountain roads.

Application of self loading mixer truck

Self-loading mixer trucks have a wide range of applications, including but not limited to the following aspects:

Construction projects: In the construction of houses, tunnels, slope protection, ports, etc., it can add raw materials (cement, sand, aggregate, etc.) into the mixing tank of the self loading mixer, mix them evenly through the mixing blades, and then transport the concrete to the construction site on site.

Road and bridge construction: In the construction of transportation infrastructure such as roads, bridges and highways, self-loading concrete mixer trucks are widely used in the construction of concrete pavements, roadbeds and bridges.

Water conservancy projects: It can also be used in the construction of concrete dams, water canals, power stations, pumping stations and other water conservancy projects to ensure the sturdiness and durability of the structure.

Industrial facilities: It provides the concrete materials quickly for floor laying, concrete flooring and foundation construction in factories, warehouses and logistics centers.

Municipal engineering: In the repair, new construction and expansion projects of urban roads, it can provide the required concrete and ensure the quality and smoothness of the roads.

Choose the right self loading concrete mixer

With the wide application of self-loading mixer trucks, more and more investors intend to buy it. So, what should you pay attention to when choosing a self loading mixer?

Model selection

Choosing the model of self loading mixer truck mainly depends on the size of your project. The size of the self loading mixer actually refers to the size of the mixing tank, which determines how many cubic meters of concrete it can produce per batch.

Our common self-loading mixer truck models include 1.2 cubic meters, 2.6 cubic meters, 3.5 cubic meters, 4 cubic meters, etc. A 4 cubic meter self loading concrete mixer means that the equipment's output is 4 cubic meters per batch. If the project size is small, you can choose a small mixer truck.

In addition, customers also need to consider whether to choose a front cab or a rear cab. For self-loading mixer trucks with a front cab, the operator can clearly observe its loading and unloading. For self-loading mixer trucks with a rear cab, the cab seat can rotate 360 degrees, and the operator can realize two-way driving.

Configuration selection

When choosing a self loading concrete mixer truck, you also need to pay attention to its configuration, including tank, reducer, hydraulic motor, radiator, chassis, gearbox, tires, etc. The choice of these accessories affects the quality of the self loading truck.

Generally speaking, the quality of the tank mainly refers to the thickness of the tank. Nowadays, the commonly used material for tanks is 6 mm thick manganese plate. If it is less than this thickness, the service life of the equipment may be affected. Choosing accessories from well-known brands can better ensure the quality and working performance of the self-loading mixer truck.

Manufacturer selection

Why is the choice of self-loading mixer truck manufacturer also crucial? This is because a reliable manufacturer can not only give you appropriate suggestions when you make a choice, but also provide you with competitive prices and considerate services.

Whether in the process of purchasing or using a self-loading mixer truck, you may encounter some problems. If you can find a reliable manufacturer, you can get relevant technical support in a timely manner.

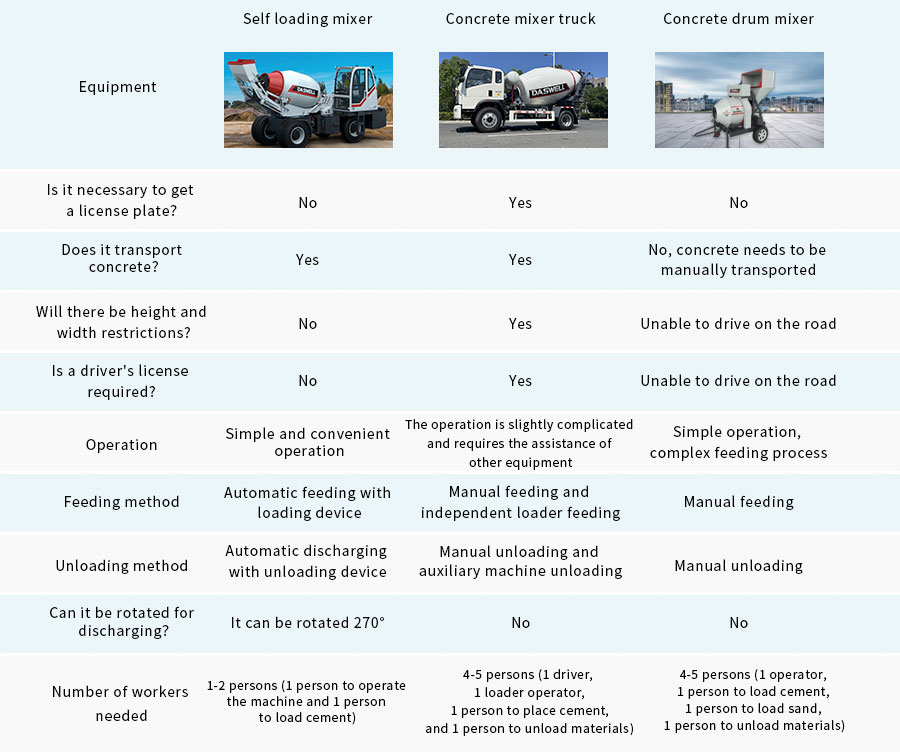

Self loading mixer VS Concrete mixer truck VS Concrete drum mixer

If you have other questions about self loading mixer trucks, please feel free to leave us a message!