The hot mix asphalt plant is the hot sale asphalt production equipment. So what is the hot mix plant? Hot asphalt mixing plant needs the heated aggregate. That means that the aggregate needs to be heated before mixing. Our Daswell SAP series hot asphalt plant is stationary type, batch mixing, designed to produce high quality asphalt with different proportions and ingredients. SAP series hot mix plant for road construction is mature, reliable and featured by high efficiency, large output and high quality finished asphalt mixture. This type of plant is fit for road construction projects in all grades and scales, especially for large-scale and high-grade road construction project.

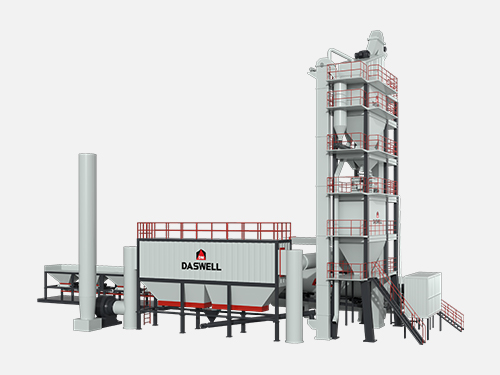

SAP3000 hot mix plant

SAP3000 hot mix plant

| Model | SAP3000 |

| Productivity(t/h) | 240 |

| Total Power(Oil)(kw) | 570 |

| Tower Power(Coal)(kw) | 650 |

| Space Needed(L×W)(m) | 35×55 |

| Total Height(m) | 27 |

Characteristics of hot mix plant

- Modular design; convenient for transportation and installation; fit for worldwide use;

- Precise screening, accurate measurement, batch mixing; producing good quality finished asphalt mixture;

- Filer and additives such as dye pigment, fibres and foam can be fed into mixer, producing finished asphalt in different ingredient and color;

- Optimized drying drum structure, thermal insulation layer surface, sufficient heating, and less heat loss;

- Dual-shaft mixer, fast and evenly mixing;

- PLC system, three control modes: manual, semi-auto and auto; easy and flexible to operate;

- Two stage dust collector, gravity dust collector and bag house dust collector, dust emission≤20mg/Nm3.

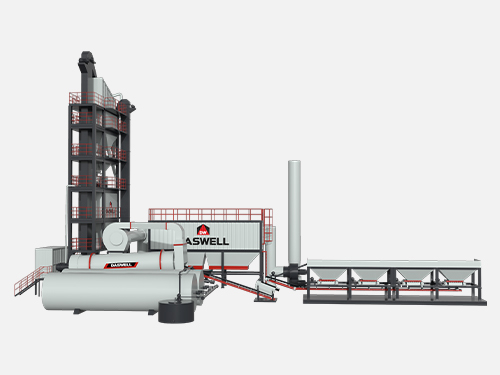

SAP1000

SAP1000

hot mix asphalt plant

hot mix asphalt plant

| Model | SAP1000 |

| Productivity(t/h) | 80 |

| Mixer Capacity(kg) | 1000 |

| Total Power(Oil)(kw) | 280 |

| Tower Power(Coal)(kw) | 315 |

| Space Needed(L×W)(m) | 30×40 |

| Total Height(m) | 21 |

SAP1500

SAP1500

the finished product storage

the finished product storage

| Model | SAP1500 |

| Productivity(t/h) | 120 |

| Mixer Capacity(kg) | 1500 |

| Total Power(Oil)(kw) | 339 |

| Tower Power(Coal)(kw) | 365 |

| Space Needed(L×W)(m) | 30×43 |

| Total Height(m) | 23 |

Main components of hot mix bitumen plant

Feeders of hot mix asphalt batch plant are equipped with vibration motor and shortage alarm device, ensuring continuous aggregate supply; protective grille is installed to protect feeder and prevent body injury. Motors on drying drum adopt central lubricating system; drive devices have protective cover; inner structure is optimized, making drying drum safe and efficient and longer service life; drying drum surface is covered by a thermal insulation layer, less heat loss. Our hot mix plant for sale is equipped with two stage dust collecting system: gravitational dust collector + bag house dust collector; better dust removal effect, dust emission is lower than 20mg/Nm3; bag house adopt NOMEX bags, high temperature resistant and durable.

Normally, a mixing tower is consists of screening layer hot aggregate storage layer, weighing layer, mixer layer, finished asphalt storage layer and loading layer; each layer is an individual module, convenient for installation and transportation. Twin-shaft mixer, the two shaft synchronously rotate in different direction, ensuing uniform mixing; paddles on the shafts are made of wear-resistant material, sturdy and durable. PLC control system of hot mix asphalt plants, easy to operate; control mode can be switched between manual, auto and semi-auto; commercial computer are equipped and operation softwares support English, French, Russian, Spanish and other languages.

SAP2000

SAP2000

batch mix hot plant

batch mix hot plant

| Model | SAP2000 |

| Productivity(t/h) | 160 |

| Mixer Capacity(kg) | 2000 |

| Total Power(Oil)(kw) | 465 |

| Tower Power(Coal)(kw) | 525 |

| Space Needed(L×W)(m) | 35×55 |

| Total Height(m) | 25 |

SAP3000

SAP3000

hot mix asphalt plant

hot mix asphalt plant

| Model | SAP3000 |

| Productivity(t/h) | 240 |

| Mixer Capacity(kg) | 3000 |

| Total Power(Oil)(kw) | 570 |

| Tower Power(Coal)(kw) | 650 |

| Space Needed(L×W)(m) | 35×55 |

| Total Height(m) | 27 |

How much does a hot mix plant cost?

The hot mix plant price is one of the most concerned factors for most of customers. So how much does an asphalt hot mix plant cost? How to minimize your price? Here are some aspects your should be concerned with.

First of all, you should check the specifications of your hot mix asphalt plant for sale. There are a variety of types and models of hot drum mix plant for your selection. The asphalt hot mix plant for sale you choose needs to fit for your projects. Its specification will affect the asphalt hot mix plant price.

Then, the hot mix plant manufacturer is also extremely important. For example, our Daswell Machinery has our own branch office in Philippines, which can provide you better after-sale services. Moreover, you can get a favorable quotation.

Finally, you also need to consider the daily maintenance. If you purchase a bad-quality drum type hot mix plant, you will spend more maintenance costs. Many factors have an effect on the hot mix asphalt plant price. Therefore, you should take these factors into consideration. If you have no idea about buy your plant at the most favorable price, welcome to contact us!

SAP4000

SAP4000

work in the site

work in the site

| Model | SAP4000 |

| Productivity(t/h) | 320 |

| Mixer Capacity(kg) | 4000 |

| Total Power(Oil)(kw) | 710 |

| Tower Power(Coal)(kw) | 796 |

| Space Needed(L×W)(m) | 38×56 |

| Total Height(m) | 31 |

SAP5000

SAP5000

large size plant

large size plant

| Model | SAP5000 |

| Productivity(t/h) | 400 |

| Mixer Capacity(kg) | 5000 |

| Total Power(Oil)(kw) | 790 |

| Tower Power(Coal)(kw) | 870 |

| Space Needed(L×W)(m) | 38×56 |

| Total Height(m) | 31 |

How to choose your construction site properly?

Choosing the suitable construction site is important. Of course, how to plan your site is equally important. When you choose the site, you need to be familiar with the route to the construction site because as a raw material, the transportation distance of asphalt mixture will directly affect the quality of asphalt when used. Then you need to pay attention to the environment around the construction site. In the process of producing and processing asphalt, there will be some noise and dust, so the location of the site should be avoided as far as possible, such as schools and residential areas.

In addition, you need to take into account the problem that hot mix asphalt station will need to use water and electricity. So choose a convenient place to use water and electricity. To sum up, you want to find a credible manufacturer to buy a good-quality hot mix asphalt plant, leave your message to us!