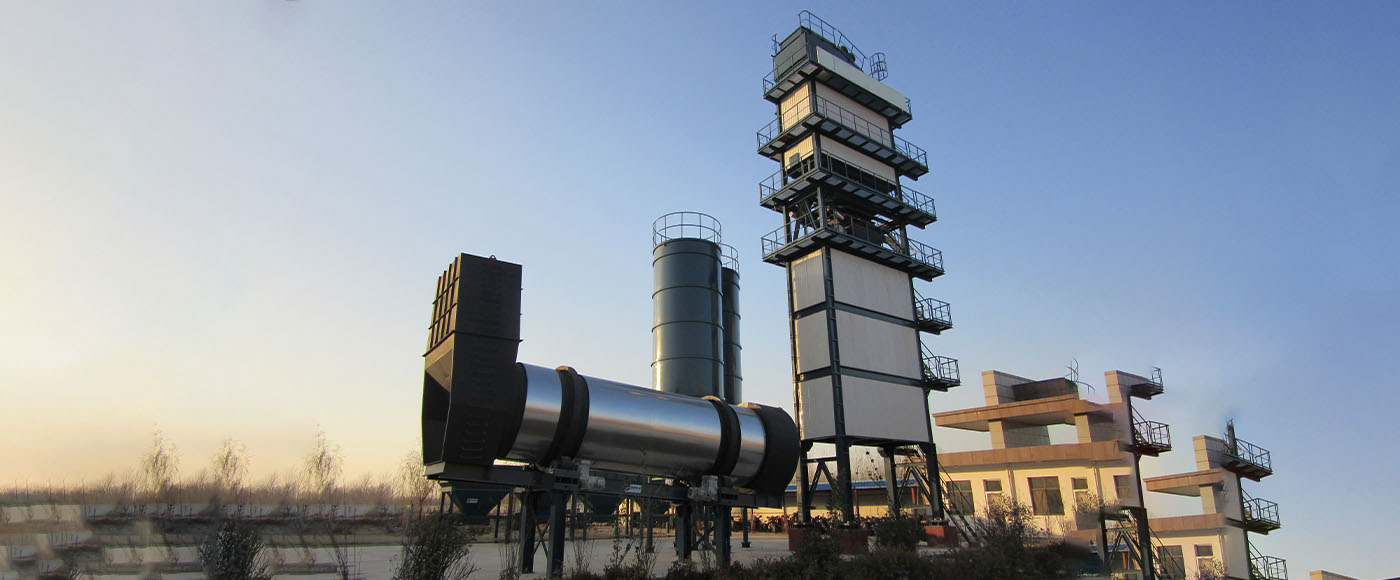

Stationary asphalt mixing plant can produce kinds of asphalt mixture in batch, such as, modified asphalt mixtures, colored asphalt mixtures, etc. Different from mobile type asphalt plant machine, the stationary asphalt plant is fitter for those projects that don’t need to transport the plant frequently. Its productivity ranges from 40t/h to 400t/h. So if your project needs large quantities of asphalt mixtures, the stationary asphalt plants for sale is a suitable choice for you. When you plan to but this plant, you need to choose a right plant depending on your actual needs in advance. Welcome to contact us if you need it!

batch mix type

batch mix type

drum mix type

drum mix type

Check its types and specifications

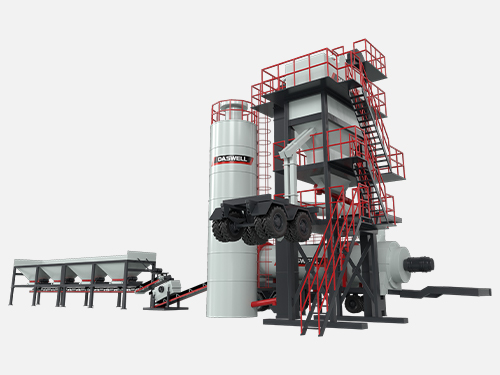

As you know, the stationary asphalt batch mixing plant includes batch mix type and drum mix type according to their different mixing methods. Different types of plants have different features and are suitable for different projects. Batch mix type stationary asphalt batching plant adopts modular design. The overall sealing effect of the mixing building is good, which improves the mute and dust proof effect. So the quality of asphalt mixtures produced by batch mix plant is high. It is the choice equipment for the construction of high-grade highways.

The production output of stationary batch type asphalt mixing plant is large, so it is also can work for those large size of projects. What’s more, its specifications include SAP1000, SAP1500, SAP2000, SAP3000, SAP4000, SAP5000, etc. Drum mix type stationary asphalt mixing plants can achieve continuous production, greatly improving the working efficiency. This type of plant has wide use on the township roads construction, the low-grade roads construction, etc. Its production capacity ranges from 40t/h to 100t/h. Meanwhile, its models include MADP-40, MADP-60, MADP-80, MADP-100, etc. Purchase a right plant.

SAP3000

SAP3000

| Model | SAP3000 |

| Productivity(t/h) | 240 |

| Total Power(Oil)(kw) | 570 |

| Tower Power(Coal)(kw) | 650 |

| Space Needed(L×W)(m) | 35×55 |

| Total Height(m) | 27 |

SAP1000

SAP1000

| Model | SAP1000 |

| Productivity(t/h) | 80 |

| Mixer Capacity(kg) | 1000 |

| Total Power(Oil)(kw) | 280 |

| Tower Power(Coal)(kw) | 315 |

| Space Needed(L×W)(m) | 30×40 |

| Total Height(m) | 21 |

SAP1500

SAP1500

| Model | SAP1500 |

| Productivity(t/h) | 120 |

| Mixer Capacity(kg) | 1500 |

| Total Power(Oil)(kw) | 339 |

| Tower Power(Coal)(kw) | 365 |

| Space Needed(L×W)(m) | 30×43 |

| Total Height(m) | 23 |

Characteristics of stationary asphalt plants

- Rigorous modular design and integral steel structure foundation make the layout more reasonable. And its disassembly, transportation and installationare more convenient and fast

- Ingenious drying drum plate design and advanced self-developed combustion heating technology not only improve the efficiency of stationary asphalt drum mix plant, but also reduce energy consumption.

- The design of hot aggregate lifting and powder lifting with plate chain improves the service life of the hoist.

- The stationary bitumenproduction equipment adopts advanced pulse dust removal technology. This makes the dust discharge low and meets the environmental protection standard.

- Our stationary asphalt mixing plants for saleis equipped with automatic and manual control systems with self-diagnostic feedback procedures for simple and stable operation.

- The core components are made of well-known national brands, such as electrical components from Siemens and weighing sensors from METTLER TOLEDO, Switzerland, which reduce the failure rate of the stationary asphalt batch mix plantand extend the service life of the equipment.

aggregate batching machine

aggregate batching machine

control system

control system

SAP2000

SAP2000

stationary asphalt batch mix plant

stationary asphalt batch mix plant

| Model | SAP2000 |

| Productivity(t/h) | 160 |

| Mixer Capacity(kg) | 2000 |

| Total Power(Oil)(kw) | 465 |

| Tower Power(Coal)(kw) | 525 |

| Space Needed(L×W)(m) | 35×55 |

| Total Height(m) | 25 |

SAP4000

SAP4000

its finished product bin

its finished product bin

| Model | SAP4000 |

| Productivity(t/h) | 320 |

| Mixer Capacity(kg) | 4000 |

| Total Power(Oil)(kw) | 710 |

| Tower Power(Coal)(kw) | 796 |

| Space Needed(L×W)(m) | 38×56 |

| Total Height(m) | 31 |

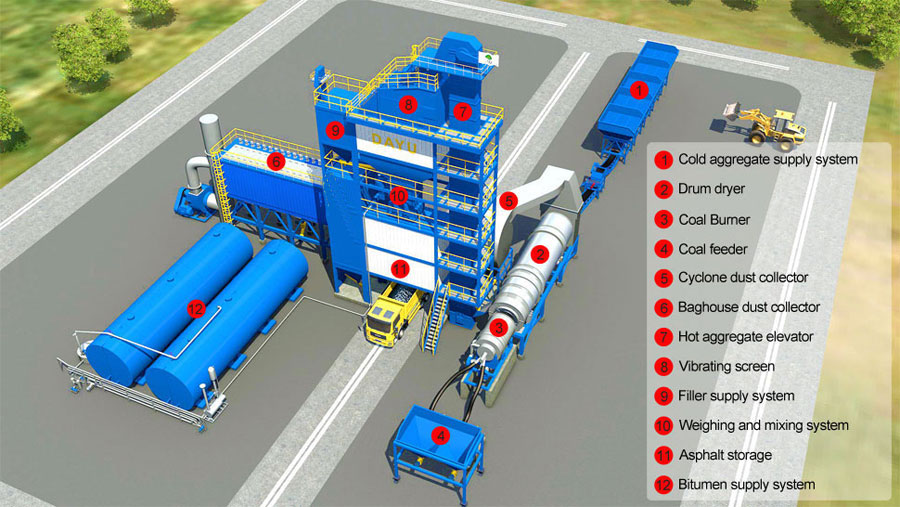

Components of stationary asphalt mixing plant

Our stationary hot mix asphalt batching plant mainly includes: cold aggregate supply system, dry drum, combustion system, hot aggregate lifting system, sieving system, weighing system, mixing system, dust removal system, powder supply system, asphalt supply system, electrical control system, finished product silo, etc. Although the standard models of stationary asphalt plant is equipped with the standard components, there are some components you can choose depending on your needs. I will introduce them for your.

The dust removal system has different options for your selection. These two options includes gravity dust removal and cloth bag dust removal, gravity dust removal and water dust removal. The combustion system includes four options, oil burner, gas burner, pulverized coal burner, oil and gas burner. Different countries and regions have different fuel resources. So you need to choose the suitable burner.

In addition, we have two different finished product bins for your selection, namely, side-placed finished products bin and under-placed finished product bin. The use of finished product silo can improve the production efficiency of mixing equipment and accelerate the turnover of transport vehicles.

components of stationary asphalt

plant

components of stationary asphalt

plant

MADP60

MADP60

drum mix type plant

drum mix type plant

| Model | MADP40 | |

| Capacity(t/h) | 60 | |

| Weighing Accuracy(%) | Aggregate | ±1.5 |

| Asphalt | ±1 | |

| Total Power(kw) | 128 | |

| Fuel Consumption(kg/t) | Coal | 10~13 |

| Oil | 5.5~7 |

MADP40

MADP40

| Model | MADP40 | |

| Capacity(t/h) | 40 | |

| Weighing Accuracy(%) | Aggregate | ±1.5 |

| Asphalt | ±1 | |

| Total Power(kw) | 75 | |

| Fuel Consumption(kg/t) | Coal | 10~13 |

| Oil | 5.5~7 |

MADP80

MADP80

| Model | MADP80 | |

| Capacity(t/h) | 80 | |

| Weighing Accuracy(%) | Aggregate | ±1.5 |

| Asphalt | ±1 | |

| Total Power(kw) | 165 | |

| Fuel Consumption(kg/t) | Coal | 10~13 |

| Oil | 5.5~7 |

Notice something when you operate this plant

You may encounter some problems in the course of using a stationary asphalt batch mix plant. So in order to avoid these problems, you need to pay attention to these aspects. In order to ensure the production capacity of stationary asphalt mixing plant, you need to pay attention to whether the proportion of various raw materials is appropriate, whether the water content of sand is too high, whether the equipment operating parameters are set correctly, etc. If you purchase a high-quality stationary asphalt batching plant, only you use it correctly, you can get the high-quality asphalt mixtures.

In the process of asphalt mixture production, there are very strict requirements on temperature. No matter the temperature is too high or too low, you can’t get the high-quality asphalt mixtures. Therefore, during the production process, operators need to accurately control the heating temperature of asphalt and sand. The operation training is very vital for your operators.

transport the MADP40

transport the MADP40

transport to

Philippines

transport to

Philippines