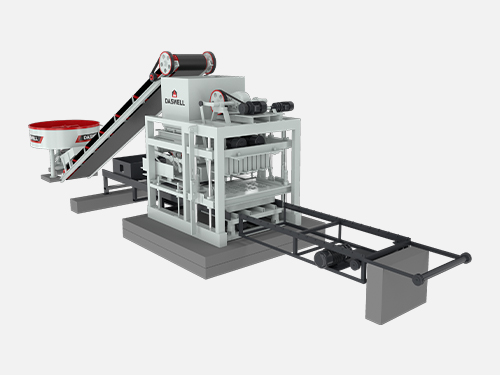

Automatic brick making machine adopts advanced technology and control system, making the operation become simpler. So investing in an automated brick making machine is a good choice for you because it can not only help you finish your projects quickly, but also reduce the labor intensity and cost. According to its automated degree, our automatic bricks making machine includes fully automatic type and semi automatic type. BMM series automatic block making machine has always been in demand since it appeared on the market. Now, I will introduce this type of block machine in detail.

BMM6-15

BMM6-15

| Model | BMM6-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1080-1440 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8861 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4500-5100 |

| Pallet Size(mm) | 900×700 |

| Exciting Force(KN) | 65 |

| Overall Power(KW) | 28 |

Fully automatic type VS Semi automatic type

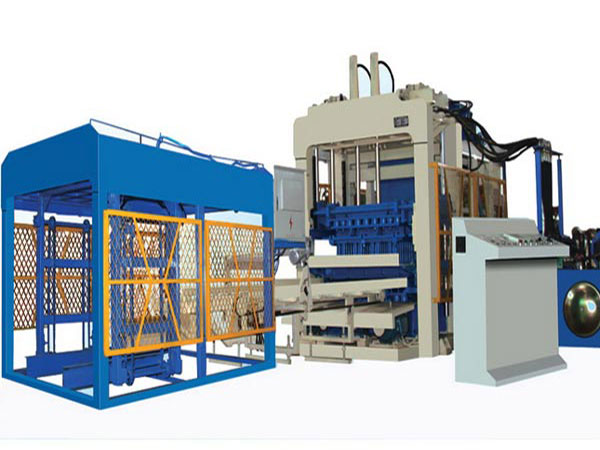

Fully automatic block making machine is a kind of high automatic degree product, which is more suitable for those medium and large size of projects. Fully automatic brick making machine has higher working efficiency and production output. It can totally meet the demand of bricks for those large projects. Moreover, the fully automatic brick machine is equipped with PLC control system. Advanced technologies makes the production process more accurate and efficient. If you have a set of fully automatic brick making plant, you just need to hire three or four workers to operate the whole process.

transport BMM4-15 to Philippines

transport BMM4-15 to Philippines

deliver the main components

deliver the main components

BMM4-15

BMM4-15

| Model | BMM4-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 720-960 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 5930-6720 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4600 |

| Pallet Size(mm) | 1020×570 |

| Exciting Force(KN) | 55 |

| Overall Power(KW) | 27.5 |

Different from fully automatic type, semi automatic block making machine is more suitable for those small or medium size of projects. Although the production output of semi automatic brick machine for sale is lower than fully automatic type, it also can meet the bricks demand of those small projects. In addition, the biggest advantages of semi automatic brick making machine is its low price. Customers can pick up the right type and model of automatic concrete block machine for their own projects. Of course, if you have no idea, you also can consult us. Maybe we will give you more professional advice.

BMM8-15

BMM8-15

| Model | BMM8-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1200-1600 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 9000-10000 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 950×900 |

| Exciting Force(KN) | 85 |

| Overall Power(KW) | 51 |

BMM10-15

BMM10-15

| Model | BMM10-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1440-1800 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 11011-12480 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

Features of automatic brick machine

- Its down-mould adopts the vertical, directional vibrating device while the up-mould used the pressure vibrating. So the blocks made by the automatic brick manufacturing machineare high in density and has good compression.

- Its products can be piled up 3~5 layers immediately after they are shaped.

- Automatic material discharging system greatly increases its efficiency.

- With fly ash and other industrial waste, it can produce color cart road bricks, lawn blocks, solid bricks, hollow blocks, etc.

- No chimney to protect the environment and avoid pollution.

- Small investment cost and quickly return. As long as you use the automatic brick plantaccording to our instruction, you can get the great profits from our this machine fast. Therefore, even if you don’t have enough money now, we also provide various of models for your selection.

electronic components

electronic components

driven engine

driven engine

BMM6-15 automatic block plant works in Mexico

Factors affecting the automatic brick machine price

When purchasing an automatic brick machine production line, you also need to learn its price firstly. As we all know, there are many factors affecting the automatic block making machine price, such as, types, models, brand, transportation route, regular maintenance, etc. So you can minimize your fully automatic block making machine price from each step. First of all, you should select a right type and model of automatic block brick machine. Before choosing the equipment, you can learn some information about automatic machine for brick from local suppliers or through the Internet. If you want to choose a suitable model of product, learning the production capacity the model of block machine is very important.

BMM5-15

BMM5-15

BMM5-15 in production factory

BMM5-15 in production factory

| Model | BMM5-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 900-1200 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8800 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×570 |

| Exciting Force(KN) | 60 |

| Overall Power(KW) | 32 |

Then, choose a suitable port and transportation route. Different port and transportation route will have an effect on the automatic brick making machine price. At last, the regular maintenance is also crucial. Regular maintenance can not only prolong the machine service life, but also reduce your maintenance cost. Choose our Daswell Machinery, you can enjoy the considerate service, good quality automatic brick making machine for sale and affordable price.

BMM12-15

BMM12-15

| Model | BMM12-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1728-2160 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 12700-14400 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1300×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

Look for a reputable automatic brick machine manufacturer

There are two ways to find the automatic brick machine manufacturers, online and offline. No matter which kind of way you choose, if you want to learn more detailed information about this automatic brick machine manufacturer, you’d better visit their office or factory. By visiting their factory, you can directly learn the production process of auto brick making machine and its quality. Good quality auto bricks machine china all are equipped with good spare parts.

In addition, the reviews of their customers is also important. If their customers speaks highly of their automatic brick making plants and their service, the manufacturer is reputable. Like our Daswell Machinery, as a experienced automatic brick machine supplier in Philippines, our products and service all have won good reputation from our customers. And now, we have our own office and warehouse in Philippines. If you are interested in our machine and you are convenient, warmly welcome to visit our office in Philippines or China. Leave your message to us and we will reply you as soon as possible.