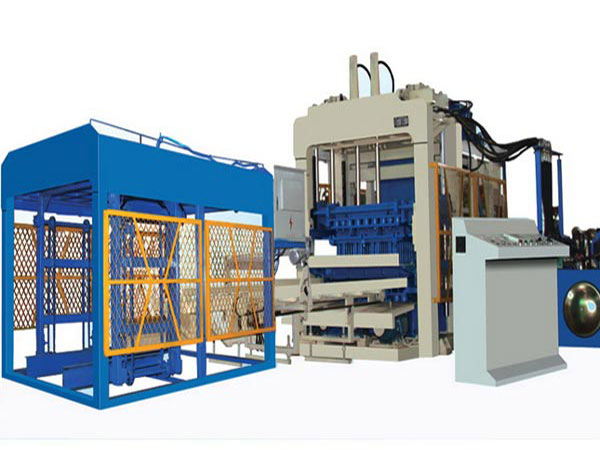

Concrete block machine for sale adopts the fly ash, cement, sand, crushed stone, construction waste, etc as its raw materials. This can not only reduce your original raw materials cost, but also achieve the comprehensive utilization of resource. Moreover, our concrete block making machine for sale adopts twin shaft concrete mixer machine, which can produce high-quality concrete bricks. These concrete bricks can be used in various of construction projects like building construction. More customers plan to invest in a concrete block manufacturing plant because of its reliable performance and high production efficiency.

BMM5-15

BMM5-15

automatic concrete machine

automatic concrete machine

| Model | BMM5-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 900-1200 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8800 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×570 |

| Exciting Force(KN) | 60 |

| Overall Power(KW) | 32 |

BMM4-15

BMM4-15

| Model | BMM4-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 720-960 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 5930-6720 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4600 |

| Pallet Size(mm) | 1020×570 |

| Exciting Force(KN) | 55 |

| Overall Power(KW) | 27.5 |

the raw materials

Different types and models of concrete block machines

Our concrete block making plant has many different types and models for your selection. According to its mobility, we have stationary type and mobile type concrete block plant. According to its control system, our stationary concrete block moulding machine for sale includes fully automatic type and semi automatic type. Among these types of concrete block molding machine, BMM series automatic concrete block making machine is the most popular. Automatic concrete block machine can help you finish your projects quickly because of its high production capacity. If you have a large size of projects, fully automatic concrete block making machine is an ideal choice for you. On the contrary, it is a wise choice for you to purchase a semi automatic concrete block making machine.

BMM6-15

BMM6-15

BMM6-15 concrete block production plant

BMM6-15 concrete block production plant

| Model | BMM6-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1080-1440 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8861 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4500-5100 |

| Pallet Size(mm) | 900×700 |

| Exciting Force(KN) | 65 |

| Overall Power(KW) | 28 |

BMM8-15

BMM8-15

| Model | BMM8-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1200-1600 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 9000-10000 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 950×900 |

| Exciting Force(KN) | 85 |

| Overall Power(KW) | 51 |

Mobile concrete brick making machine is good for those small projects. It has the characteristics of convenient movement, easy operation and energy saving. Moreover, the mobile concrete block machine for sale doesn’t need the pallets. This can not only reduce your purchase cost for pallets, but also save the labor to put pallets.

DMBE-12A

DMBE-12A

mobilt type block machine

mobilt type block machine

| Model | DMBE-12A |

| Molding Quantity | 12pcs/mould(400*200*200mm) |

| Cycle Time | 25s |

| Production Capacity | 1700pcs/hour |

| Operation Pressure | 16-20Mpa |

| Vibration Mode | Excitation |

| Demolding mode | Hydraulic |

| Total Power | 17.5Kw |

| Total Weight | 5100KGS |

Contact us and help you pick up the most suitable concrete brick making machine for sale for your project.

How to purchase a right concrete block machine for sale?

Before purchasing a concrete bricks machine, there are some questions you should know. The answers of these questions will help you pick up a right concrete block making machine for sale. First of all, you should know what type of bricks you want to produce. Different types of concrete making machine can produce different types of bricks. For example, some models of mobile concrete block machine just can produce hollow bricks while some can produce both hollow bricks and solid bricks. So you should ensure the type of bricks you need.

| Model | BMM6-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1080-1440 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8861 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4500-5100 |

| Pallet Size(mm) | 900×700 |

| Exciting Force(KN) | 65 |

| Overall Power(KW) | 28 |

Then, consider the size of bricks and the productivity of concrete block making plant. Size of bricks and the production output will decide on the suitable model of your concrete block plant for sale. Next, you should know what type of concrete block machine for sale you need, stationary type or mobile type. Compared with stationary type, you can more easily transfer the mobile concrete block manufacturing plant among different sites. At last, pay more attention to the molds. You should tell the manufacturer whether you need the extra molds in advance. These factors all can affect the concrete block making machine price.

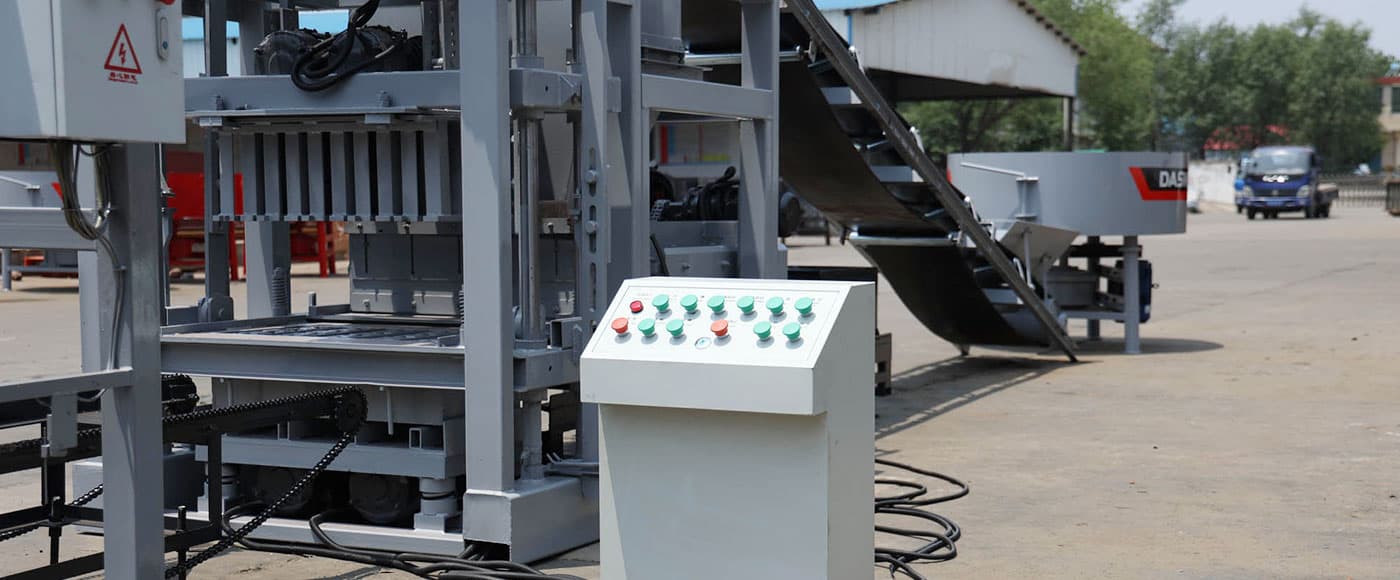

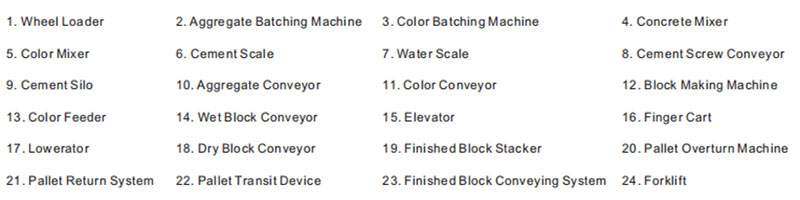

Components of a complete of concrete block production line

A complete of concrete block production plant includes not only a set of concrete bricks machine for sale, but also other related equipment. Here are a picture of fully automatic block production line. As we can see from this picture, a complete concrete block production plant includes wheel loader, aggregate batching machine, concrete mixer, concrete block maker machine, cement silo, pallets, conveyor equipment and so on.

Our concrete mixer machines all adopts twin shaft concrete mixer, which has better stirring quality. Moreover, our concrete mixer machine has many models for your choose. What’s more, we also provide you with various of cement silo, including 30t, 50t, 100t, 200t, etc. We also can customize the concrete block machine for sale if you have any extra requirement.

aggregate batching machine

aggregate batching machine

concrete mixer

concrete mixer

cement silo

cement silo

How to make a good concrete bricks?

The working principle of concrete block making machine is simple. You can learn the working process briefly.

Firstly, weigh the raw materials though the aggregate batching machine and transfer the weighed materials to the mixer machine. Then, the concrete mixer machine stirs these materials thoroughly and evenly. Next is the block molding process. You can get various sizes and shape of bricks through different molds. At last, transfer the wet block by the finger cart. After block curing, the finger cart also transports the finished dry blocks. The whole process is finished. You can put these bricks into use.

BMM10-15

BMM10-15

| Model | BMM10-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1440-1800 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 11011-12480 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

BMM12-15

BMM12-15

| Model | BMM12-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1728-2160 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 12700-14400 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1300×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

In order to ensure the quality of finished bricks, you should purchase a good quality of concrete brick making plant and operate it following the instruction.

For a customer who wants to purchase a concrete block brick machine, the price is important. If you are interested in our concrete block machine for sale, welcome to leave your message to us. After receiving your email, our sales manager will contact us and give you a reasonable quotation!