Cone crusher for sale is the useful machines with high working efficiency when producing aggregate materials. Moreover, it is also a very important part of a complete crushing production line. The cone crusher machine can crush all kinds of very hard ores and rocks, such as, calcite, limestone, granite, river pebbles, dolomite, basalt, iron ore, etc. It is mainly used for medium crushing and fine crushing.

In order to meet the demand of different customers, the cone crushers for sale includes different types and cone crusher specifications, such as, single cylinder hydraulic crusher, multi-cylinder hydraulic crusher, Simmons cone crusher and so on. The cone crusher plant has wide use on the sand and stone yard, concrete sand, dry mortar, construction waste, sand mechanism, power plant desulfurization and other industries.

Daswell cone crusher in factory

Advantages of the cone crusher for sale

- Big reduction ration. The combination of high performance crushing chamber and high crushing frequency can greatly improve the processing capacity of the cone crusher equipment, which single unit of the cone crushercan produce 2181 tons per hour.

- Laminating crushing, good grain shape. This cone stone crusher adopts the principle of material lamination crushing, so the broken products are mostly cubic structure, which reduces the material of pin sheet to a greater extent.

- Simple structure and easy to maintain. It has the features of simple structure and convenient operation and maintenance. And the adjustment of discharge port is also convenient and quick, saving time and effort in maintenance. In particular, the liner is easy to replace, reducing downtime.

- Equipped with hydraulic overload protection, do not damage the equipment. The spring safety system of the cone rock crushers for saleensures that the equipment can not be damaged easily when the non-crushing foreign body passes through the crushing chamber or the machine is overloaded for some reason.

different types and models of cone

crusher

different types and models of cone

crusher

| Type | Dia. of Cone (mm) | Adjusting Range of Discharge Opening (mm) | Max Feed Size (mm) | Capacity (t/h) | Motor Power (kw) | Weight (t) | Overall Dimension (mm) |

| SCS-600 | 600 | 12-25 | 65 | 15-25 | 30 | 5.5 | 1740×1225×1940 |

| SCF-600 | 3-13 | 36 | 5-23 | 30 | 5.5 | 1740×1225×1940 | |

| SCS-900 | 900 | 15-50 | 115 | 50-90 | 55 | 10.18 | 1990×1640×2380 |

| SCM-900 | 5-20 | 60 | 20-65 | 55 | 10.19 | 1990×1640×2380 | |

| SCF-900 | 3-13 | 40 | 15-50 | 55 | 10.27 | 1990×1640×2380 | |

| SCS-1200 | 1200 | 20-50 | 145 | 110-200 | 110 | 24.7 | 2805×2300×2980 |

| SCM-1200 | 8-26 | 100 | 50-150 | 110 | 25 | 2805×2300×2980 | |

| SCF-1200 | 3-15 | 50 | 18-105 | 110 | 25.6 | 2805×2300×2980 |

Cone crusher VS Jaw crusher

The cone crushers and the jaw crusher are the most commonly used crushing equipment. So how to distinguish these two different crusher machines? And what is the difference between these two devices?

First of all, different structure. A jaw crusher consists of a fixed and moving jaw. For the cone crusher parts, they have similar cones on the jaws of the jaw crusher. However, the main difference here is that the cone crushers uses both cones to grind rocks and ores into smaller pieces.

Then, different operation. Having a jaw crusher machine, the movable jaw drives the corresponding jaw plate while the fixed jaw operates in the opposite swinging motion. The cone crusher for sale philippines, alternatively, uses the rotating oscillatory motion. The strain on the stones responds when caught in between the two cones.

Finally, different feeding and discharging size. As said before, a jaw crusher is used for primary crushing purposes. Here, the stones employed for the input are larger in size. A mobile cone crusher is mostly utilized for secondary crushing. However, the discharging size is smaller when compared to jaw crusher.

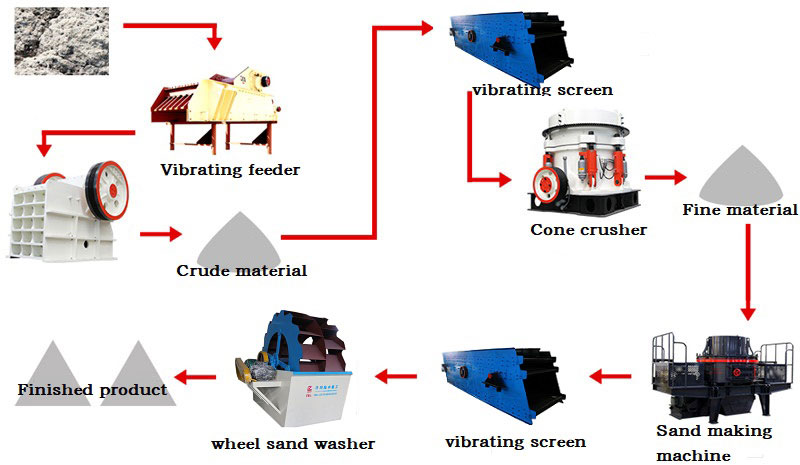

Complete cone crushing production line

The mobile cone crusher plant is the important part for the whole cone crushing production line. For some customers, they want to look for the trusted cone crusher manufacturers who can help them design a suitable cone crushing production line. A complete cone crushing production line provided by good cone crusher suppliers consists of the feeding equipment, crushing equipment, transportation equipment, screening equipment and so on. The engineers can design the layout of the whole production line according to the size of your site.

Of course, you can pick up the suitable cone crusher machine depending on the needs of your projects because it includes the three types, namely, the coarse crushing, the medium crushing and fine crushing. In recent years, the mobile crushing production line with affordable cone crusher price becomes more and more popular due to its mobility and reliable performance. If you are interested and want to learn more detailed information, welcome to contact us now!

complete cone crushing production line

complete cone crushing production line

| Model | Cavity Type | Stroke(mm) | Max. Feeding Size(mm) | Discharging Opening Adjusted Scope(mm) | Capacity(t/h) | Motor Power(kw) | Weight(t) |

| CS1400C | Coarse | 30 | 235 | 30-60 | 210-530 | 220 | 25 |

| CS1400M | Medium Coarse | 30 | 215 | 25-50 | 200-500 | 220 | 25 |

| CS1200C | Coarse | 22 | 180 | 19-50 | 110-250 | 132 | 16 |

How does a cone crusher work?

In the working process of cone crusher for sale, the motor drives the eccentric sleeve to rotate through the transmission device. The moving cone rotates and oscillates under the forced action of the eccentric sleeve. The section where the dynamic cone is close to the static cone becomes the crushing chamber. And the material is crushed by many extrusion and impact of moving cone and static cone. When the moving cone leaves the section, the material to be crushed to the required size falls under the action of its own gravity and is discharged from the bottom of the cone crusher. After learning how the cone stone crusher equipment works, the operator can use the machine more efficient and safer.

the working process

the working process

Importance of routine maintenance

If you want to use your cone crusher equipment with the competitive cone crusher cost for a very long time, besides choosing a high-quality machine, the routine cone crusher maintenance is also equally important. Regular maintenance can not only make you find the problems of the cone crusher philippines, but also increase its life span. So how?

transport the cone crusher to other country

transport the cone crusher to other country

Keep the hydraulic cylinder and hydraulic oil clean. Hydraulic cylinder needs to use a closed device, and in accordance with the requirements of the cone crusher hydraulic system to choose the right hydraulic oil. When hydraulic oil is added to the hydraulic system, it must be filtered strictly with a clean oil filter and then added into the hydraulic cylinder. Moreover, whether it is summer or winter, the mobile cone crusher for sale should be run to heat up the lubricating oil, At the same time, the cooling system will keep the oil temperature in the safe operating range. If you want to know more maintenance methods, you can contact us to get more! Leave your message here!