Whether from the local area or on the Internet, you can find many manufacturers of concrete batching plants. But you will find that the prices of the concrete mixing plants they provide are all different, and there are even big differences. This is because the price of the concrete plant is affected by many factors, such as model, configuration, etc.

Many customers are also concerned about the price of a concrete batching plant before buying it. Therefore, this article will introduce some content related to the concrete plant price.

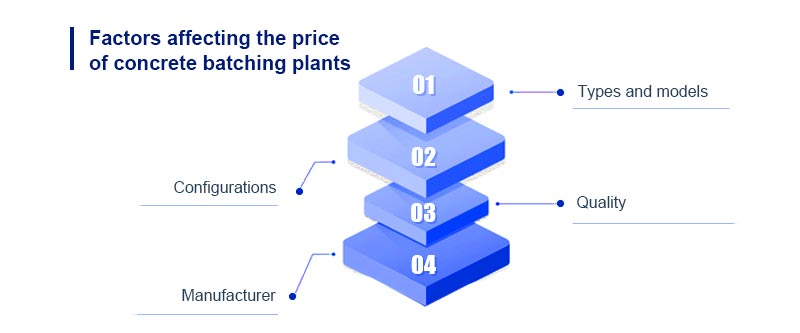

Factors affecting the concrete batching plant price

First of all, the factor that has a greater impact on the price of a concrete batching plant is its type and model. As we all know, concrete batching plants can be divided into stationary batching plants and mobile batching plants. You will find that even if the two concrete plants have the same output, their prices are different. In addition, the output of the concrete plant ranges from 25 cubic meters per hour to 240 cubic meters per hour. The larger the model, the larger the output, and the higher the price.

Secondly, concrete mixing plant can have different configurations. Whether you choose a fully automatic control system or a semi-automatic control system, an ordinary mixer or a vertical shaft mixer with better mixing quality, this will affect the concrete plant price.

Then, some investors may find that from the quotations provided by different manufacturers, their concrete plants look as if there is no difference, but the prices vary a lot. This is because the quality of their concrete plants is different. A reliable manufacturer will use high quality parts to assemble the concrete mixing plant. This will effectively increase the service life of the concrete plant.

Finally, the prices of concrete plants offered by different manufacturers are also different. Because the production cost, operation cost and brand promotion cost of different manufacturers are different, so the price they offer is also different.

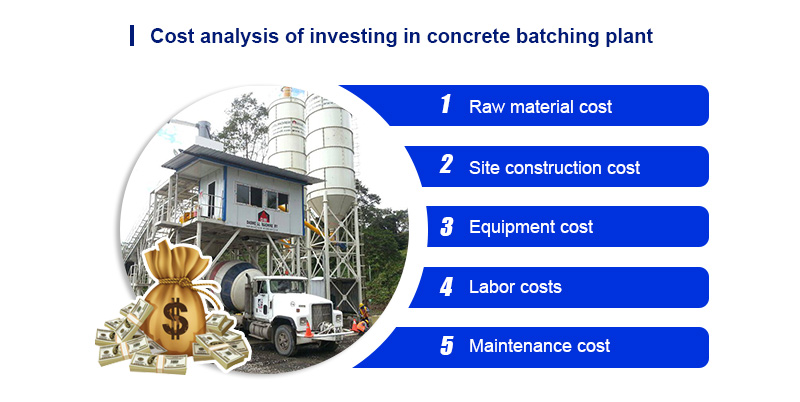

Cost analysis of concrete batching plant

When you are ready to invest in a concrete batching plant, you need to consider the cost of investment. Generally speaking, the cost of a concrete plant generally involves the following aspects.

Raw materials cost

The cost of raw materials is an important part of the cost of a concrete batching plant. It mainly depends on the price of the local market, which requires buyers to compare the quotations provided by different manufacturers to make the best choice. In addition, when purchasing raw materials, the distance between the location of the raw materials and the site of the batching plant should also be considered, which will affect the transportation costs of the raw materials.

Site construction cost

Before installing a concrete batching plant, you need to find a suitable production site, and then lease or buy the site. Secondly, you need to plan and layout the site so that the batching plant can be installed in the appropriate location. At the same time, you also need to consider the cost of water and electricity on the construction site, and transportation cost of the finished product .

Equipment cost

When buying a batching plant, you need to consider your investment cost, and then choose a batching plant with the right price. In addition to this, you also need to consider the infrastructure costs before installing the batching plant. For example, before the installation of the stationary plant, it is necessary to lay the foundation and do the hardening of the site.

Labor cost

Because of the automatic control system of the concrete batching plant, only a few workers can be employed to operate the entire production line. Labor costs are relatively low.

Maintenance cost

During the operation of the equipment, some problems will inevitably occur, which requires regular maintenance and inspection of the concrete mixing plant. If parts are worn out, they need to be replaced in time. If the concrete plant fails, it needs to be shut down for inspection, which needs to consider the economic loss during the shutdown.

Lower the average cost and increase the profits

How to improve the profit margin of concrete mixing plant? This is the question that many investors are pondering. In fact, the answer is to increase the production efficiency of your concrete batching plant so that you can reduce your average production costs and start increasing your revenue.

Ensure adequate supply of raw materials. If there is a shortage of raw materials during the production process, it will not only reduce the production efficiency but also affect the progress of the project.

Control the mixing time. The mixing time required for concrete of different strengths is different. Therefore, it is necessary to precisely control the mixing time of different concretes, otherwise it will affect the overall production efficiency.

Ensure operator proficiency. Operators need to go through professional operation training before work, to ensure that they can operate the concrete mixing plant independently.

Regular inspection and maintenance of the concrete mixing plant. Regular inspection and maintenance of the concrete plant can detect problems in time and avoid downtime due to machine failure.

Configure enough concrete mixer trucks. Customers should equip enough mixer trucks according to the production capacity and transportation distance of the concrete plant to prevent the production of too much commercial concrete from not being transported in time and affecting the progress of the project.

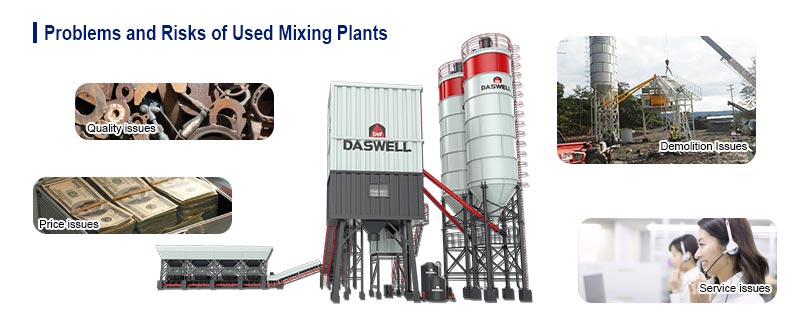

Is It Cost-effective To Buy A Used Or A New Concrete Batching Plant?

In order to save investment costs, some investors may consider buying used concrete plants. But, is it more cost-effective to choose a used batching plant or a brand new one? We recommend that it is more cost-effective to buy a brand new concrete batching plant. This is because a used concrete plant can expose you to a lot of problems and risks.

Quality issues

When the concrete batching plant is in brand new condition, it can achieve the best performance in terms of operation and so on. The second-hand batching plant may have some problems in the previous operation. You can't guarantee that these problems will not recur, thus affecting the quality of the concrete batching plant and its production efficiency.

Price issues

Typically, manufacturers of used concrete plants will refurbish all the parts in order to sell them at a higher price. However, the quality of used parts and equipment degrades with frequency of use, so you may end up spending a lot of money on the maintenance of a used concrete plant.

Demolition issues

The used concrete batching plant needs to be demolished and relocated first. This will not only increase your cost, but will inevitably cause some damage to the concrete mixing plant during the process of dismantling and reinstalling.

Service issues

Some customers may want to sell the plant again after their project was completed and the plant was put on hold. In this case, they are not able to provide you with corresponding after-sales service. This will increase your maintenance cost if you find another professional repairer.

So, you continue to want to buy a used concrete mixing plant, you need to ask yourself the following questions:

- Is the quality of the used batching plant guaranteed?

- Is it worth the price?

- Will its maintenance costs exceed the profits it brings?

If you still don't know how to choose, please contact us, we will provide you with professional help!