Before operating the asphalt plant, the operator must not only undergo professional skill training, but also be familiar with the structure and working process of the asphalt plant. On this basis, strictly control each production steps, regularly maintain the asphalt plant, and ensure the quality of the asphalt mixture produced.

So, what should a qualified asphalt plant operator do in different stages of production?

Management of raw materials

The raw materials of asphalt plant are mainly aggregates, powders and bitumen. The management of raw materials mainly involves how to ensure the quality of raw materials and safe production in all aspects of storage, transportation, loading and unloading, and inspection.

Sampling of raw materials

The sampling of asphalt raw materials shall ensure the representativeness of the materials. Asphalt tanks should have dedicated sampling valves and samples should not be taken from the top of the asphalt tank. Before sampling, 1.5 liters of asphalt should be drained to flush contamination from valves and pipes. Sampling containers should be clean and dry.

Aggregate storage, transportation and management

Aggregate should be stacked on a hard and clean site, and the stacking site should also have good waterproof and drainage facilities. Fine aggregates should be covered with rain shelter cloth, and aggregates of different specifications should be separated by partition walls.

When stacking materials with a bulldozer, it should be noted that the thickness of each layer should not exceed 1.2 meters, and the disturbance to the aggregate should be as little as possible.

Each batch of incoming materials should be sampled and analyzed, and can only enter the construction site after being certified as qualified. The grading characteristics of the material pile should be checked periodically during construction and monitored for changes.

Control of raw material supply

- The loader operator should load from the side of the pile where no coarse material rolls down. When loading, the bucket inserted into the pile should be piled up with the boom, and then backed up. Do not excavate by turning the bucket to reduce material segregation.

- For parts where obvious coarse material segregation has occurred, it should be remixed before charging. The loader operator should always keep each cold material bin full and prevent material mixing during loading.

- Under the rated production rate, the speed of the feeding belt should be maintained at a medium speed, and the range of speed regulation should not exceed 20-80% of the maximum speed.

- Mineral powder should prevent moisture absorption and agglomeration, so the compressed air used for arch breaking can only be used after water separation. The powder in the mineral powder conveying device should be emptied after the completion of the project.

- Before running the mixing equipment, you should start the heat-conducting oil furnace to warm up the asphalt in the asphalt tank to the specified temperature and preheat all parts of the asphalt feeding system. When starting the asphalt pump, close the oil inlet valve and start it at idle, then slowly open the oil inlet valve and load it gradually. At the end of the work, the asphalt pump should be reversed for several minutes in order to pump the asphalt back into the asphalt tank.

Management of drying and heating systems

- When the equipment starts to run, the drying drum should be started by manual control when the cold material supply system is shut down, and the burner should be ignited to preheat the cylinder with a low fire for 5 to 10 minutes before loading. When loading materials, the amount of feed should be gradually increased, and the oil supply should be gradually increased according to the temperature of the hot material at the outlet, until the specified production capacity and stable temperature are reached, and then the automatic control mode is switched.

- When the cold material system suddenly stops feeding or other accidents occur during the work, the burner should be turned off first to let the drum continue to rotate and the induced draft fan continue to pump air, and then shut down the machine after the cylinder is completely cooled. At the end of the work the machine should be shut down gradually in the same way.

- When the water content of cold material is high, the automatic control system will be out of control and the temperature will oscillate up and down, so it should be changed to manual control and the residual water content of hot material should be checked. If it is too high, the production volume should be reduced.

- The residual moisture content of hot aggregate should be checked regularly especially in rainy days, and the residual moisture content should be controlled at less than 0.1%.

- The exhaust gas temperature should not be too high or too low, generally controlled at about 135 ~ 180 ℃. If the exhaust gas temperature remains high and the aggregate temperature rises, it is mostly caused by the water content of cold material is too large, and the production volume should be reduced in time.

- The pressure difference between inside and outside of the bag filter should be kept within a certain range. A large pressure difference indicates that the bag is seriously blocked and needs to be processed and replaced in time.

Management of hot aggregate storage system

Check whether the hot material screening system is overloaded, whether the screen is blocked or has holes. If it is found that the material accumulation on the screen surface is too high, stop the machine and adjust it.

The mixing rate of the hot aggregate bin should be checked by regular sampling, and the mixing rate should not exceed 10%.

Management of metering and mixing systems

- The weighing data of each batch of mixture recorded by the computer can detect whether the work of the measurement system is normal. Every day after the machine is turned on to work steadily should print 2 hours of continuous weighing data, and analyze its system error and random error. If finding beyond the requirements, the operator should promptly check the work of the system, analyze the causes and be eliminated.

- After the mixer works every day, it should be scrubbed with hot mineral materials to remove the residual asphalt in the mixing tank. Usually, the coarse aggregate and fine aggregate should be washed 1 or 2 times respectively.

- When using the lifting hopper to unload the mixture into the finished bin, the hopper must stop at the center of the bin to unload. Otherwise, the finished asphalt will have longitudinal segregation in the bin, i.e. the coarse material will roll to one side of the bin.

- When unloading from the finished product bin, the unloading door should be opened quickly, not allowing the mixture to flow slowly to avoid segregation.

- When unloading to the truck, it is not allowed to unload to the center of the tank. It should be unloaded to the front of the tank and then to the rear, and then unloaded in the center.

Control of finished asphalt mixture

- The asphalt pump should meet the principle of pumping and uniform spraying, and can meet the requirements of the heating temperature of the lower layer of asphalt at 160°C~170°C and the heating temperature of mineral materials at 170°C~180°C.

- The asphalt mixture should be mixed uniformly, with black and bright color, no white material, no agglomeration or separation of coarse and fine aggregates.

- During the mixing production process, the operator can pay attention to monitoring the data of various instruments at any time, observe the working status of various machinery and the color and shape of the factory mixture, and make timely adjustments when abnormalities are found.

- During the production process, the quality of the material, the temperature of the mixture, the mixing ratio and the ratio of oil to stone shall be inspected according to the frequency and method required by the regulations, and records shall be made respectively.

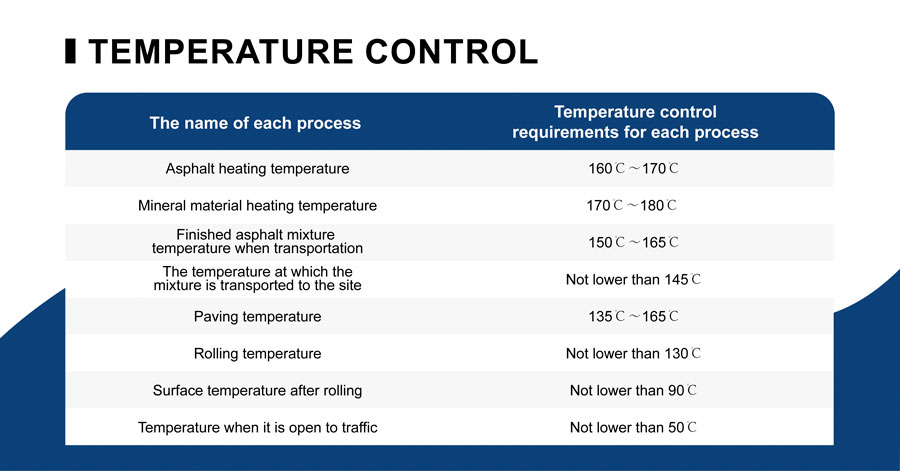

Temperature control in production

Management of dump truck when loading

The trucks for transporting asphalt mixture are all over 15t, meeting the requirement of large tonnage insulation. Cover with tarpaulin insulation during transportation. In order to prevent the asphalt from sticking to the carriage, after cleaning the bottom and side panels of the carriage, evenly apply a thin layer of heat transfer oil and water mixture, and clean the wheels.

When the dump truck is loading materials at the discharge port, move the parking spaces in the order of front, back and middle, and do not pile up materials to reduce the segregation of coarse and fine aggregates. After the dump truck is loaded and the temperature is measured, the asphalt mixture is tightly covered with thermal insulation tarpaulin and sent to the construction site immediately.

If you want to know more about the asphalt plant, please feel free to contact us!