The stationary concrete pump is also named trailer pump, which is the popular machine in Philippines. Duing using this pump, you may meet some problems. Below is a list of possible problems and corresponding solutions. If you encounter these problems, you can also try to solve them.

We will introduce some of the problems that can occur with concrete pumps according to their different systems.

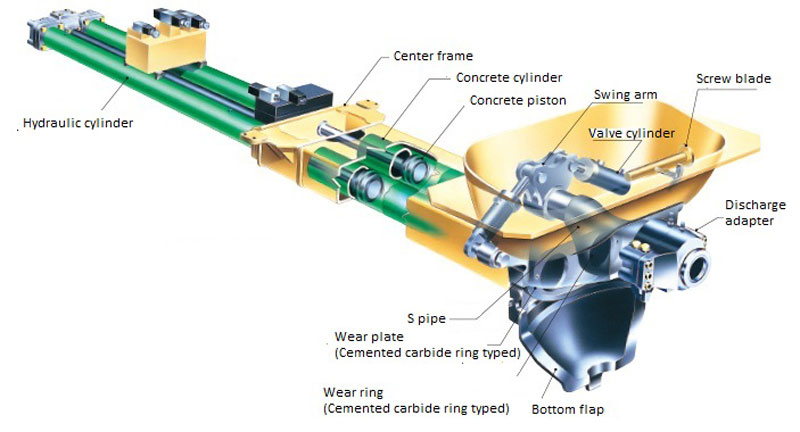

Pumping system

Faults: Pumping cylinder pistons do not move.

Reasons:

- Pumping start-up button failure and loose connection. Disconnected wires and wet electrical components.

- Fault of solenoid directional valve, usually because valve spool is jammed or solenoid bums out.

- Turn the-knob of reducing valve too much, so the control pressure is too low.

- Hydraulic oil inside the oil tank is too little.

- Suction filter element is seriously jammed.

Solutions:

- Tighten cable terminal, dry electrical system components and replace pumping start-up button.

- Remove and clean the valve spool, or replace the solenoid.

- Adjust the-knob of reducing valve.

- Refill hydraulic oil and keep the oil level above 3/4 of oil level indicator.

- Replace filter element.

Faults: Pumping cylinders don’t change direction.

Reasons:

- The gap between the proximity switch and piston flange is too big or they don’t contact.

- The bottom of the proximity switch is adhibitted by grease or other foreign materials, which makes induction not sensitive.

- Proximity switch is failure or ther switches position is wrong (especially when the machine is switched from high pressure state to the low pressure state, operator forgets to interchange the proximity switches position).

- The solenoid coil of the solenoid directional valve bums out.

Solutions:

- Adjust the gap between 2~3mm.

- Clean the bottom of the proximity switch.

- Replace the proximity switch or interchange the switches position.

- Replace the solenoid.

Faults: Pumping cylinder pistons move slowly and weakly.

Reasons:

- The wear of the charge pump elements causes too little oil filling.

- Tum the knob of reducing valve too much, so the control pressure is too low.

- The pressure of the control oil is not enough.

- When pumping concrete to higher storey, due to no oil conpensation. Hydraulic oil in the close chamber of pumping cylinder decreases, and the stroke of pumping cylinder becomes shorter and shorter.

Solutions:

- Replace the charge pump elements which are worn.

- Adjust the knob of reducing valve.

- Adjust the control system again: The pressure of the relief valve on the charge pump is adjusted 2.5Mpa and the pressure of the flush valve is adjusted 2Mpa.

- Inch the hydraulic cylinder for several times to refill oil.

Faults: Bad situation for concrete output: pumping discontinuously or low conveying volume.

Reasons:

- The concrete piston are worn out.

- The gap between the spectacles wear plate and cutting ring is too large.

- Concrete is so bad that the suction of concrete is too bad.

- S tube has been blocked partly. If the pumping pressure rises to 32Mpa suddenly.

Solutions:

- Replace the concrete pistons.

- Adjust gap.

- Adopt pumpable concrete.

- Reverse pumping must be done for 2-3 times at once by turning REVERSE PUMPING, then normal pumping be done. If the pumping pressure is still too high after reveres pumping has been done for several times, it shows that the concrete pipeline may be blocked, we must stop pumping and clean the pipeline.

Faults: The center of the hydraulic cylinder is deflective.

Reasons:

- The mechanism position of the servo valve of the main oil pump is not centered.

- The hydraulic position of the servo valve of the main oil pump is not centered.

Solutions:

- Adjust the mechanism position of the servo valve of the main oil pump to zero.

- Adjust the hydraulic position of the servo valve of the main oil pump to zero.

Distributing system

Faults: S tube does not swing.

Reasons:

- Fault of hydraulically operated direction control valve, usually because valve spool is jammed.

- S tube is blocked by objects.

- The failure of relief valve causes the swing pressure not enough.

- The failure of constant pressure pump cause swing pressure not enough.

- Poor concrete pumped and stop machine for a long time, that increase swing resistance, so S tube can’t swing.

- Bearing of S tube worn out, that increases swing resistance.

- The horizontal concrete pipes is too short when concrete is pumped to higher storey.

Solutions:

- Remove and clean the valve spool.

- Clean the objects.

- Readjust the relief valve pressure or replace relief valve.

- Check and repair the constant pressure pump, replace the wear parts and readjust the pressure of the constant pressure pump.

- Clear the poor concrete in hopper.

- Stop machine and replace bearing.

- Lengthes horizontal concrete pipes or add an bend pipe at the outlet of hopper.

Mixing system

Faults: Due to poor pumpable characteristic, mixing resistance is very big or mixing blades are blocked.

Solution: When they are blocked, rotate the blades reversely.

Faults: The setting pressure of relief valve is not enough.

Solution: Use wood to block blade and readjust the pressure to 14Mpa.

Faults: Mixing motor has been damaged or the gear for mixing system is damaged.

Solution: Check and replace it if necessary.

Faults: Mixing turning button failure, loose connection, electrical system components are moist.

Solution: Tighten cable terminal, dry electrical system components and replace mixing turning button.

Main electric and hydraulic components

| Components | Faults | Solutions |

| Auxiliary relay | Coil or contactor is damaged, so contractor can not close and disconnect normally. | Replace it. |

| Solenoid | Solenoid is burnt out. | Replace the solenoid which is burnt out. |

| Proximity |

1、 The bottom of the promixity switch is adhibitted by oul which makes induction not sensitive. 2、 The gap between the proximity switch and piston flange is too big, which makes induction not sensitive. 3、 The temperature of the water tank is very high, which makes wrong action occur and S tube swing disorderly. 4、 It is damaged completely, which can’t indure, or it is always in connection. |

1、 Clean the bottom of the proximity switch. 2、 Adjust the gap between 2~3 mm. 3、 Adjust the temperature of the water tank. 4、 Replace the proximity switch. |

| Accumulator |

1、 The accumulator pressure is not enough. 2、 Bladder is damaged. |

1、 Add the air pressure. 2、 Change the bladder. |

If you want to get more information about static pumpcrete machine, welcome to contact us directly. We are glad to answer any question at any time!