The twin shaft concrete mixer can be used for stirring all kinds of dry concrete, plastic concrete, fluidity concrete, light aggregate concrete and various mortar. With the development of social infrastructure construction, more and more customers need to invest in a twin shaft mixer that can help them produce high-quality concrete quickly. Nowadays, the twin shaft batch mixer plays an important role in the different fields, such as all kinds of small and medium-sized prefabricated parts factories and highways, bridges, water conservancy, ports, docks, construction sites, etc. Therefore, if you want to find a reliable manufacturers, welcome to choose our company now!

Daswell twin shaft concrete mixer in

factory

Daswell twin shaft concrete mixer in

factory

Check our its specifications

The specifications of our twin shaft paddle mixer is TCM series. It includes small size, medium size and large size for different size of projects. Its models have TCM500, TCM750, TCM1000, TCM1500, TCM2000, TCM3000, TCM4000, etc. Before purchasing, you need to know what model of double shaft mixer your project need.

If you have no idea, you also can consult a reliable manufacturer and ask him for help. When you check out its specification, you also should notice the related parameters, such as feeding capacity, discharging capacity, production capacity, motor power, max. aggregate particle size, discharging height, etc. These factors can affect the model of twin shaft concrete mixer for sale you buy. If you need a lot of finished concrete in the certain time, we suggest you choose a large size of twin shaft mixer for sale.

TCM500

TCM500

| Model | TCM500 |

| Charging Volume(L) | 800 |

| Discharging Volume(L) | 500 |

| Max. Aggregate Size(mm) | 40/50 |

| Weight(t) | 4 |

| Mixing Power(kw) | 18.5 |

| Dimension(mm) | 3050×2530×2680 |

| Mixing Time(s) | ≤72 |

TCM750

TCM750

| Model | TCM750 |

| Charging Volume(L) | 1200 |

| Discharging Volume(L) | 750 |

| Max. Aggregate Size(mm) | 40/60 |

| Weight(t) | 5.5 |

| Mixing Power(kw) | 30 |

| Dimension(mm) | 3110×2620×2580 |

| Mixing Time(s) | ≤72 |

Advantages of twin shaft concrete mixers

- Stir more evenly and efficiently. Our twin shaft mixer concreteadopts double helix continuous blade instead of traditional shovel blade, which has high mixing efficiency and good evenness. This reduces the stirring time by more than 50% and improves the mixing uniformity by about 15%.

- Good sealing. Our mixer adopts the new shaft end sealing technology, which has good sealing effect and increases the service life of the machine.

- Less stirring noise. Our machine is equipped with a hydrostatic starter, so there is less stirring noise. And the stirring material is directly in the unloading port after the stirring, the unloading time is short.

- Better wear resistance. When the mixer agitates, most of the concrete is piled up between the two shafts, resulting in less wear between the arm and blade and the bottom cost, with only slight wear.Therefore, our mixer liner is more than three times more durable than other products in the same industry.

our mixers in workshop

our mixers in workshop

transport the mixer

transport the mixer

TCM1000

TCM1000

| Model | TCM1000 |

| Charging Volume(L) | 1500 |

| Discharging Volume(L) | 1000 |

| Max. Aggregate Size(mm) | 80/100 |

| Weight(t) | 5.2 |

| Mixing Power(kw) | 18.5×2 |

| Dimension(mm) | 2810×3200×1920 |

| Mixing Time(s) | ≤30 |

TCM1500

TCM1500

| Model | TCM1500 |

| Charging Volume(L) | 2250 |

| Discharging Volume(L) | 1500 |

| Max. Aggregate Size(mm) | 80/100 |

| Weight(t) | 5.8 |

| Mixing Power(kw) | 30×2 |

| Dimension(mm) | 3230×2000×1920 |

| Mixing Time(s) | ≤30 |

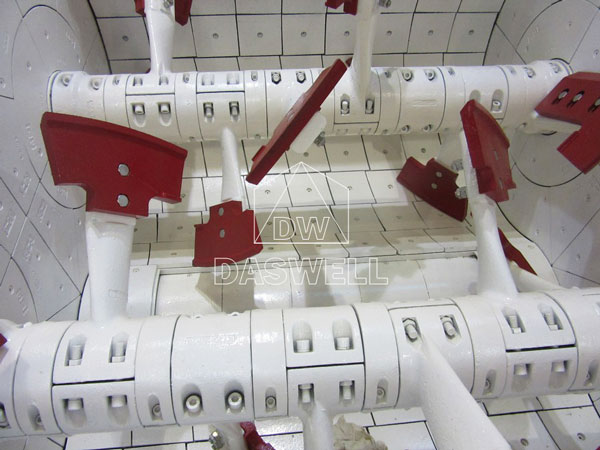

Components of twin shaft concrete mixer

The twin shaft continuous mixer mainly consists of feeding system, mixing system, unloading system, water supply system and electrical system. The feeding system consists of hoisting machine, feeding frame, hopper, feeding nozzle, etc. Mixing system is composed of motor, pulley, reducer, agitator and so on.

Our electrical system mainly includes air switches, fuses, thermal relays and other parts, with short-circuit protection, overload protection functions. Meanwhile, the discharging system consists of discharging door, air pump, reversing valve, cylinder and other parts.

The unloading door is at the bottom of the mixer. Pneumatic unloading and the opening and closing position of the unloading door are controlled by the cylinder. The sealing of the unloading door can be guaranteed by adjusting the position of the sealing strip.

agitator shaft

agitator shaft

internal structure

internal structure

TCM2000

TCM2000

| Model | TCM2000 |

| Charging Volume(L) | 3000 |

| Discharging Volume(L) | 2000 |

| Max. Aggregate Size(mm) | 80/100 |

| Weight(t) | 7.5 |

| Mixing Power(kw) | 37×2 |

| Dimension(mm) | 3460×2320×2140 |

| Mixing Time(s) | ≤30 |

TCM3000

TCM3000

| Model | TCM3000 |

| Charging Volume(L) | 4500 |

| Discharging Volume(L) | 3000 |

| Max. Aggregate Size(mm) | 80/120 |

| Weight(t) | 9.2 |

| Mixing Power(kw) | 55×2 |

| Dimension(mm) | 3880×2600×2200 |

| Mixing Time(s) | ≤30 |

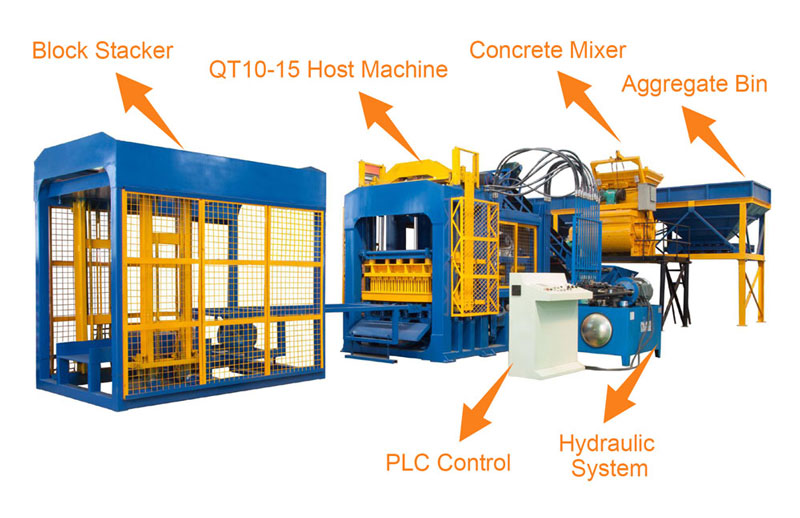

Wide application

Besides using the single twin shaft compulsory concrete mixer, it also can work as an important part of other machines, such as the concrete batching plant, the brick block making machine, etc.

For the concrete batch mix plant, after weighing different materials, including aggregate, cement, additive, water, etc, these materials are delivered into the double shaft paddle mixer. Then the mixer machine stirs them evenly. Only a high quality mobile twin shaft mixer can produce high-quality finished concrete. High-quality concrete can guarantee the quality of whole projects.

For the brick block maker machine, especially the fully automatic brick production plant, a good twin shaft concrete mixer machine is equally crucial. Only if the mixer mixes the material more evenly, the final brick will be of higher quality. Of course, the choice of mixer must also match the whole machine. For example, the HZS25 concrete batching mixing plant usually is equipped with TCM500 twin shaft batch mixer.

the twin shaft mixer of concrete plant

the twin shaft mixer of concrete plant

wide use on a brick plant

wide use on a brick plant

TCM4000

TCM4000

| Model | TCM4000 |

| Charging Volume(L) | 6000 |

| Discharging Volume(L) | 4000 |

| Max. Aggregate Size(mm) | 80/150 |

| Weight(t) | 12.2 |

| Mixing Power(kw) | 75×2 |

| Dimension(mm) | 4670×2600×2200 |

| Mixing Time(s) | ≤30 |

Purchase a right mixer machine

Buying the right machine isn’t just about choosing the right model, it’s also about choosing a reliable manufacturer. When you select the model of twin shaft concrete mixer machine, you need to be concerned about the productivity, your demand for concrete, the motor power and so on. This can help you buy a suitable model of mixer machine. In addition, you also need to find the reliable twin shaft concrete mixer manufacturers. A credible manufacturer can not only provide you with the better twin shaft paddle mixer, but also the favorable twin shaft mixer price and sincere service.

Of course, you can look for the manufacturers at home or abroad, but you should compare their products and prices. And then choose the best one. In summary, if you are interested in our twin shaft concrete mixer or you have any question about this machine, welcome to contact us to get more information!