Concrete hollow blocks is a new type of green building material, and it is also the main wall material commonly used in the construction industry. It has the characteristics of light weight, sound insulation, heat preservation, impermeability, durability, no pollution, energy saving and environmental protection. Concrete hollow blocks are widely used in construction, roads, squares, gardens and other constructions.

Hollow blocks are called hollow blocks because of the large proportion of the hole rate in the overall area of hollow bricks. Now there are many types of hollow blocks on the market, mainly cement hollow blocks, clay hollow blocks, shale hollow blocks, etc. In addition, hollow blocks also have many different shapes and sizes for customers to choose, just need to customize different molds.

Why Philippines uses hollow blocks?

Reduce the total weight of bricks

The porosity of hollow bricks (that is, the percentage of the hole area in the entire brick area) is generally 15% or more. These holes correspondingly reduce the overall weight of the entire brick. However, due to non-solid reasons, the bearing capacity of hollow bricks is not so good, so it is not recommended to use hollow bricks as load-bearing structures.

Convenient transportation and easy construction

Compared with solid bricks, hollow bricks are lighter in weight, which makes transportation more convenient. In addition, the size and shape of hollow bricks are uniform and easy to construct. Even unskilled workers can easily use hollow bricks.

Thermal insulation, sound insulation and noise reduction

Due to the unique hollow shape, concrete hollow blocks have very good thermal insulation, sound insulation and noise reduction effects. The hole in the middle will not make the sound insulation effect of the indoor wall worse, but will have a very good sound insulation effect due to the flow of air and air pressure.

Cheap price and economical

The raw materials of hollow blocks are widely sourced and relatively cheap, so compared with other decorative materials, the finished hollow blocks price is also cheaper and the economic benefit is high.

Durable

Concrete hollow blocks are mainly formed by high pressure and vibration compaction, making the bricks very strong and durable.

Environmentally friendly

Now the hollow blocks can also be called non-burning bricks. Compared with traditional fired bricks, hollow bricks reduce pollution and are very environmentally friendly.

Raw materials of hollow blocks

The raw materials of hollow bricks are very wide. Whether it is fly ash, cement, stone powder, sand, or slag, slag, coal gangue, it can be used as its raw material. As long as you can find one or two of these raw materials, you can produce hollow bricks.

Moreover, using these raw materials, you can not only produce hollow bricks, but also interlocking bricks, lawn bricks, curbstones, permeable bricks, pavement bricks, etc. The finished bricks have the characteristics of good quality, low cost and not easy to weather.

Compared with the traditional bricks made of clay, the raw materials of hollow blocks are not only easy to obtain, but also cheap. This greatly reduces the production cost of customers and also protects land resources.

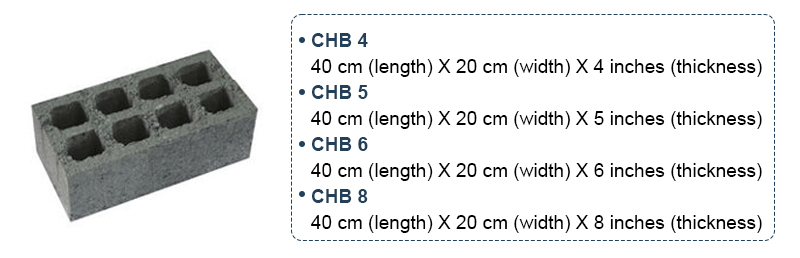

Standard size of hollow blocks philippines

There are many sizes of hollow blocks in the Philippines. But the standard sizes of hollow blocks are 4 inches, 5 inches, 6 inches and 8 inches. The details are as follows.

Of course, in addition to standard bricks, if you have special needs, the manufacturer can usually customize the mold according to your needs. You just need to tell your needs to your manufacturer before you buy the brick machine, and there will be professional engineers to customize the plan for you.

Concrete hollow block making machine philippines

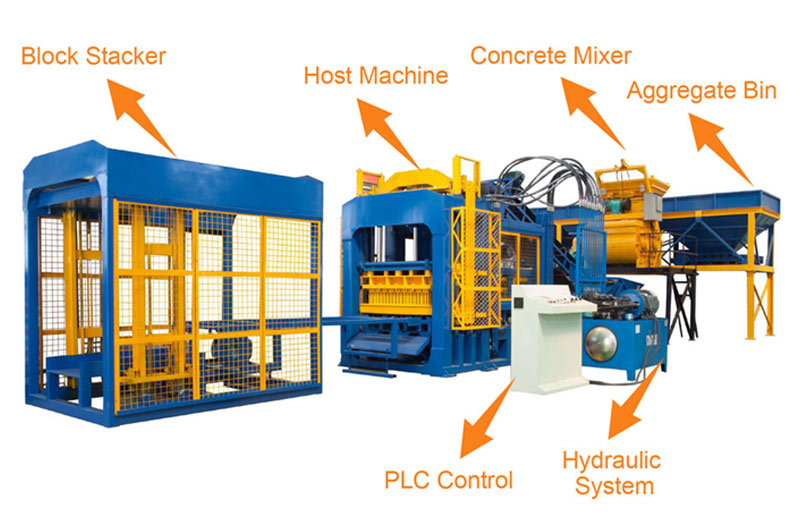

Concrete hollow block making machine can also be called non-burning brick machine. It is mainly formed by hydraulic pressure and does not need to be fired, so it is called a non-burning brick machine. The brick block machine not only reduces the pollution caused by firing bricks, but also improves the production efficiency and meets the needs of large-scale production.

According to the different operation modes, concrete hollow brick making machines can be divided into fully automatic type and semi-automatic type.

The automatic hollow block machine mainly controls the entire production process through the PLC control system. Only two to three workers are needed to operate the entire machine. It is mainly suitable for large brick business, which not only has high production efficiency and stable operation, but also reduces labor costs.

The semi-automatic hollow block machine is mainly controlled by the control panel. It has a low investment cost and is suitable for small and medium-sized brick factories. Because the operation is simple, customers can get started quickly. When you want to invest in a brick factory but the funds are not so sufficient for the time being, the semi-automatic brick machine is a good choice.

There are many models of different types of brick making machines for customers to choose from. If you want to buy a suitable brick machine, you need to consider not only the price, but also its output, floor space, configuration and other factors.

How to make hollow blocks?

The production process of hollow bricks: batching - mixing - conveying - feeding - forming - conveying - stacking - maintaining - finished product

The complete automatic hollow brick production line mainly includes batching machine, mixer, block forming machine, lifting plate system, finger cart system, lowering plate and palletizing system, etc.

Batching: The operator needs to set the ratio of different materials in the control system in advance. When different raw materials are fed into different silos of the batching machine by the loader, the materials in the silos are automatically weighed.

Mixing: The weighed material is sent to the mixer for mixing. After stirring evenly, the material is sent to the block forming machine.

Forming: The main machine of the hollow brick machine is intelligently controlled by the PLC system, and the bricks are formed by hydraulic transmission and vibration pressure. The control system can randomly adjust the parameters according to the different needs of customers. By changing different molds, the hollow brick machine can produce bricks of different types and sizes, realizing a multi-purpose machine.

Stacking: The finished bricks are palletized by a palletizer, which saves manpower and has high efficiency.

Maintaining: 24 hours after the finished bricks are palletized, they need to be maintained with water. Maintenance twice a day in spring and autumn, three times a day in summer. After 15 to 20 days, the hollow bricks are ready for use. Of course, steaming can also be carried out under conditions.

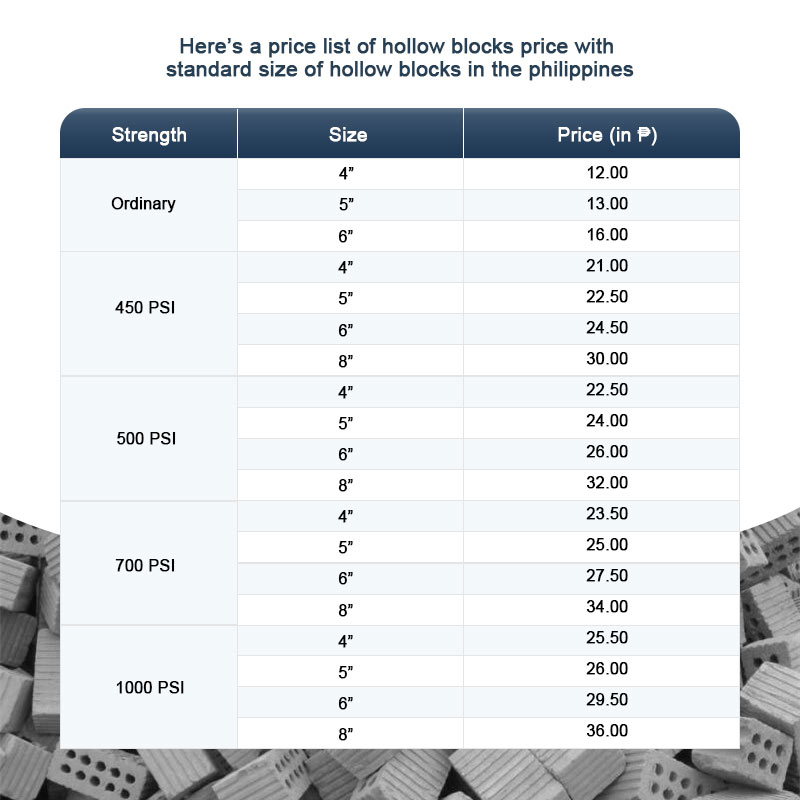

Hollow blocks price philippines

When you are ready to open a brick factory, the price of hollow bricks is also an aspect you need to pay attention to. This is because the price of hollow bricks will affect your later income. The price of hollow bricks in different regions may vary slightly. Below is a price list of standard hollow bricks in the Philippines for your reference.

If you want to know more about hollow bricks, please feel free to consult us!