Fly ash is a main raw materials for fly ash brick making machine producing various of brick blocks. Then the fly ash brick machine needs to use one or two kinds of another materials as its raw materials like cement, crushed stone, goaf, slag, construction waste, etc. Therefore, the fly ash bricks manufacturing process just needs to cost very little on the original raw materials. Our Daswell BMM series fly ash brick machinery is popular among our customers. Besides this models, we also provide you with new mobile type brick machine for sale.

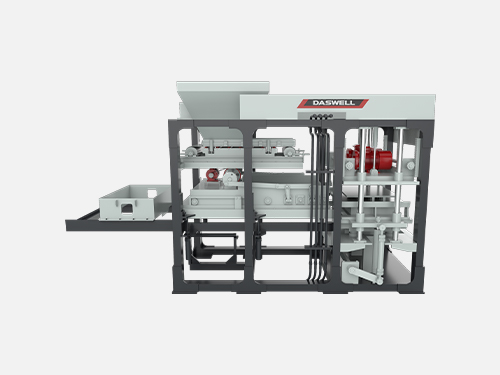

BMM4-15

BMM4-15

| Model | BMM4-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 720-960 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 5930-6720 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4600 |

| Pallet Size(mm) | 1020×570 |

| Exciting Force(KN) | 55 |

| Overall Power(KW) | 27.5 |

the raw materials

the raw materials

How to assess each fly ash bricks making machines

There are many kinds of fly ash brick making plant on the market. Purchasing a suitable type and model of fly ash brick plant is crucial for customers. So how to assess each fly ash block machine? How to judge whether a fly ash block making machine is right for you? Here are some suggestion for your reference. The assessment of each fly ash bricks machine that you find begins with the specification for each one. Each fly ash bricks manufacturing unit will have very similar parameters, with the main difference being whether or not they are fully automatic type machine or semi automatic in construction. Fully automatic fly ash brick making machines are easy to use, computer controlled, and will often have many more options and possibilities.

BMM4-15

BMM4-15

| Model | BMM4-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 720-960 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 5930-6720 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4600 |

| Pallet Size(mm) | 1020×570 |

| Exciting Force(KN) | 55 |

| Overall Power(KW) | 27.5 |

BMM5-15

BMM5-15

| Model | BMM5-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 900-1200 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8800 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×570 |

| Exciting Force(KN) | 60 |

| Overall Power(KW) | 32 |

Semi automatic fly ash bricks manufacturing machines are slightly not easy to manage, yet they are often the most reasonably priced. The specifications that you will assess will include the different types of bricks you can produce. This may include interlocking bricks, standard bricks, or hollow bricks. Also assess the size of each fly ash making machine, the number of pieces that it can produce per hour, and the cycle molding for each brick that is made.

Simple tips for obtaining one at a reasonable cost

If you want to obtain the best fly ash bricks manufacturing machine price, you need to learn different price provided by different manufacturers. After you learn its price, you need to compare these different fly ash bricks machine price. And then choose a cost-effective fly ash brick making plant. There are many ways to obtain the fly ash block making machine price, such as by mail, email, or over the phone. It is recommended that you obtain ten or more fly ash bricks making machine costs so that you have more information to access. Your evaluation will consider the speed at which the fly ash brick press machines are able to produce the bricks, and how different types of bricks they can make.

BMM6-15

BMM6-15

fully automatic machine

fully automatic machine

| Model | BMM6-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1080-1440 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 7680-8861 |

| Reated Pressure(Mpa) | 16 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 4500-5100 |

| Pallet Size(mm) | 900×700 |

| Exciting Force(KN) | 65 |

| Overall Power(KW) | 28 |

Of course, the fly ash brick making machine price is also related to its brand, its materials, its quality, its types and models and so on. So when you buy this product, you should take the fly ash bricks plant price into consideration. If you are interested in our machine, welcome to contact us to get the fly ash brick making machine quotation here.

BMM8-15

BMM8-15

control cpanel

control cpanel

| Model | BMM8-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1200-1600 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 9000-10000 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 950×900 |

| Exciting Force(KN) | 85 |

| Overall Power(KW) | 51 |

Distinguish different fly ash bricks manufacturing machine suppliers

You can get many benefits from a reliable fly ash brick machine manufacturer, such as, good machine, considerate service, etc. The assessment of fly ash brick machines manufacturers that produce this machine begins with learning more about each business. Consider their location, how long they have been in business, and how large companies will have these in stock, ready to ship, and will have many different styles. Many of these machines for fly ash bricks are capable of producing blocks and bricks of many different sizes, which might be exactly what you need.

Daswell brick machine production factory

Daswell brick machine production factory

Some fly ash brick making machine manufacturers with rich experience is reliable and trustworthy. They will recommend suitable fly ash block machine for you according to your actual needs. Moreover, their engineers also can guide you how to correctly install, debug, operate, even maintain the fly ash machine.

BMM10-15

BMM10-15

| Model | BMM10-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1440-1800 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 11011-12480 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1100×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

BMM12-15

BMM12-15

| Model | BMM12-15 |

| Capacity(for 390×190×190mm hollow block)(pcs/h) | 1728-2160 |

| Capacity(for 240×115×53mm solid brick)(pcs/h) | 12700-14400 |

| Reated Pressure(Mpa) | 21 |

| Main Vibration Form | Platform vibration |

| Vibration Frequency(rpm) | 2800-4500 |

| Pallet Size(mm) | 1300×900 |

| Exciting Force(KN) | 110 |

| Overall Power(KW) | 67 |

Reviews of our Daswell fly ash brick plant

When you judge a fly ash brick machine manufacturer, there is also important factor you should think about. That is the reviews of their customers. Up to now, our Daswell Machinery has exported many sets of fly ash block making machines to Philippines. After using a period of our fly ash bricks making machines, our customers speak high praise of our equipment. They think that our fly ash brick manufacturing machine has the advantages of stable performance, high working efficiency, high production quality, easy operation and maintenance, etc.

Daswell BMM6-15 works in Mexico

Daswell BMM6-15 works in Mexico

If you are in Philippines, we can show you around our fly ash brick making machine in local site. In addition, you also can listen to the comments from our customers. We believe that a good evaluation is the best proof of the quality of our fly ash brick machinery.

Interested in our fly ash bricks making machine? Request the best quotation here now!