Vertical shaft impact crusher is also called the sand making machine. That is because it can provide the high-quality sand or aggregate to the highway, high-speed rail, construction, municipal administration construction, water and electricity dam construction. So it is the first choice in sand making and stone shaping fields.

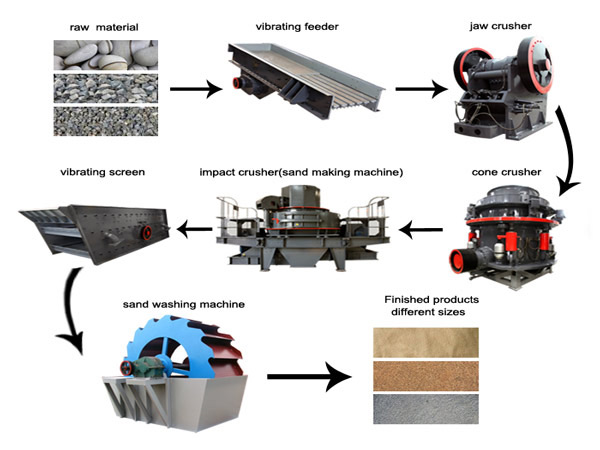

Different from other crusher machine, the feeder opening size of vertical shaft impactor is slightly smaller, generally less than 60mm. In addition, its production capacity varies from tens to hundreds of tons. In general, it can form a sand production line with vibrating feeder, cone crusher, vibrating screen and so on. Any demand, welcome to contact us now!

vertical shaft impact crusher for sale

vertical shaft impact crusher for sale

What is the vertical crusher used for?

Our vertical shaft impact crusher for sale has wide usage in different fields, as detailed below:

- Artificial sand making of river pebbles, rocks (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, stone chips;

- Machine-made sand production and stone shaping in the engineering field, including water conservancy and hydropower, high-grade highways, high-speed railways and railways, passenger dedicated lines, bridges, airport runways, municipal engineering, high-rise buildings, etc;

- Production of building aggregates, road fabrics, cushion materials, asphalt concrete and cement concrete aggregates;

- The pre-grinding fine crushing process in the mining field, namely, the crushing of materials in the building materials, metallurgy, chemical, mining, refractory, cement, abrasive and other industries;

- Production of glass, quartz sand and other high-purity materials;

- High grindstone and secondary disintegration and crushing, desulfurization in thermal power and metallurgical industries, steel slag, construction waste crushing and other environmental protection projects.

vsi rock crusher

vsi rock crusher

crusher in factory

crusher in factory

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | |

| Capacity (t/h) | Cascade and center feeding | 120-180 | 200-260 | 300-380 | 450-520 |

| Center feeding | 60-90 | 100-130 | 150-190 | 225-260 | |

| Feeder Opening size (mm) | Soft material | ≤35 | ≤40 | ≤45 | ≤50 |

| Hard material | ≤30 | ≤35 | ≤40 | ≤45 | |

| Rotation speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | |

| Power of double motors (kw) | 110-150 | 180-220 | 264-320 | 400-440 | |

| Overall dimension (mm) | 3700×2150×2100 | 4140×2280×2425 | 4560×2447×2778 | 5000×2700×3300 | |

| Vibrating sensor | Inspection scope: 0.1-20mm/s, it can be adjusted continuously | ||||

| Thin oil lubrication station | Power of double oil pump (kw) | 2×0.31 | |||

| Safety | Double oil pumps make sure supply of oil; stop automatically without oil flow or oil pressure; water cooled; heating start the motor in winter | ||||

| Overall dimension (mm) | 820×520×1270 | ||||

| Power of oil-box heater dimension (kw) | 2kw | ||||

drawing of sand production line

drawing of sand production line

Highlight advantages of vertical shaft impact crushers

- Perfect final product shape. The finished products have good shapes, mostly cubes, with reasonable grading, and adjustable product sizes, which are especially suitable for sand making and beautification of product shapes. Practice has proved that the performance of this type of sand making machine is more than 30% higher than that of other ordinary machines.

- Hydraulic device, easy for maintenance. The cover of the hydraulic device is opened, and the parts in the crushing cavity are easily repaired and replaced, which is convenient and fast, saving working time.

- Automatic detection, safe and reliable. Our vertical impact crusher for sale is equipped with over-vibration and alarm devices. When the machine runs abnormally, it will automatically alarm and stop to prevent machine damage.

- The installation and operation are convenient, the vertical shaft crusher is not heavy, and the installation methods are various. Moreover, it also can be for mobile usage.

- International quality assurance. This vsi crusher for sale adopts latest German technology and all key components adopt international famous brand. This can guarantee its service life.

transport vertical impact crusher

transport vertical impact crusher

How does a vertical shaft impact crusher work?

The vsi crusher plant adopts a unique feeding crushing structure and a variety of crushing cavities, which can easily switch between "rock to rock" and "rock to iron" crushing, achieving multi-functionality. It can be widely used in the fields of sand making, stone molding, grinding, etc. It can meet the various requirements of customers without major changes to the machine. Moreover, "rock to rock " is mainly used for processing of abrasive materials, while "rock to iron" is mainly used for processing of materials that are not abrasive.

The working principle of vertical shaft impactor crusher is as the follows. The raw material falls vertically from the upper part of the machine into the high-speed rotating impeller. Under the action of high-speed centrifugal force, it collides and smashes at high speed with another part of the material around the impeller in the form of an umbrella.

After the materials collide with each other, they will form a vortex between the impeller and the casing, and the materials will collide and rub against each other many times, and then be crushed. They will be discharged from the bottom to form a closed circuit for multiple cycles. The screening equipment controls to achieve the required finished product particle size.

VSI-7611 VSI crusher machine

VSI-7611 VSI crusher machine

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | |

| Capacity (t/h) | Cascade and center feeding | 120-180 | 200-260 | 300-380 | 450-520 |

| Center feeding | 60-90 | 100-130 | 150-190 | 225-260 | |

| Feeder Opening size (mm) | Soft material | ≤35 | ≤40 | ≤45 | ≤50 |

| Hard material | ≤30 | ≤35 | ≤40 | ≤45 | |

| Rotation speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | |

| Power of double motors (kw) | 110-150 | 180-220 | 264-320 | 400-440 | |

| Overall dimension (mm) | 3700×2150×2100 | 4140×2280×2425 | 4560×2447×2778 | 5000×2700×3300 | |

| Vibrating sensor | Inspection scope: 0.1-20mm/s, it can be adjusted continuously | ||||

| Thin oil lubrication station | Power of double oil pump (kw) | 2×0.31 | |||

| Safety | Double oil pumps make sure supply of oil; stop automatically without oil flow or oil pressure; water cooled; heating start the motor in winter | ||||

| Overall dimension (mm) | 820×520×1270 | ||||

| Power of oil-box heater dimension (kw) | 2kw | ||||

How much does a set of VSI crusher need to invest?

When you plan to invest in a vsi stone crusher, you have to consider your purchase budget. The vertical shaft impact crusher price on the market is different. Different factors will affect its price, such as equipment type, model, material type, material size, manufacturer, etc. Therefore, if you want to get a accurate quote from a vsi crusher manufacturer, you need to know your demands.

Usually, our engineers can customize the suitable sand production line for our customers. For example, the configuration of our previous customer is as follows: the vibrating feeder, cone crusher, vsi impact crusher, belt conveyor, vibrating screen, sand washer. Its raw materials are pebbles. In addition, another customer recycled leftover bits and pieces from different stone crushing plants as raw materials, so he wanted a convenient mobile machine. And then our engineer customized a mobile vsi crusher for sale plus a mobile screening station for him. So if you choose us, you can enjoy our exclusive customized service.

Any demand for the vertical shaft impact crusher, choose our Daswell Machinery without hesitate! You will get a reply as soon as possible!