When you plan to invest in a concrete batching plant, you should look for a concrete batch mix plant manufacturer to

get

one firstly. With the demand of concrete mixing plant is higher and higher, more and more concrete batching plant

manufacturers appear on the market. You can find a concrete mixing plant manufacturer in local area. Or maybe you

also

can purchase a concrete batch plant from abroad. No matter what way you choose, online or offline, we hope that you

can

find a trustworthy batch mix plant manufacturer.

CBP25

installation of cement silo

|

Model

|

CBP25

|

|

Capacity (m3/h)

|

25

|

|

Mixer

|

TCM500

|

|

Aggregate Bin

|

ABM800

|

|

Discharge Height (m)

|

3.8

|

|

Cycle Tine (s)

|

72

|

|

Weighing Accuracy(%)

|

Aggregate: ±2

|

|

Cement: ±1

|

|

Water: ±1

|

|

Additive: ±1

|

Request A Quote

How to judge the strength of a concrete batch mix plant manufacturer

Why should you judge the strength of the concrete batching mixing plant manufacturers before purchase a machine?

That is in order to help you get a satisfied machine for your project. So here is the problem, how to judge it? You

can

distinguish their strength from the following aspects.

CBP35

stationary type plant

|

Model

|

CBP35

|

|

Capacity (m3/h)

|

35

|

|

Mixer

|

TCM750

|

|

Aggregate Bin

|

ABM1200

|

|

Discharge Height (m)

|

3.8

|

|

Cycle Tine (s)

|

72

|

|

Weighing Accuracy(%)

|

Aggregate: ±2

|

|

Cement: ±1

|

|

Water: ±1

|

|

Additive: ±1

|

Request A Quote

CBP50

small size plant

|

Model

|

CBP50

|

|

Capacity (m3/h)

|

50

|

|

Mixer

|

TCM1000

|

|

Aggregate Bin

|

ABM1600

|

|

Discharge Height (m)

|

3.8

|

|

Cycle Tine (s)

|

72

|

|

Weighing Accuracy(%)

|

Aggregate: ±2

|

|

Cement: ±1

|

|

Water: ±1

|

|

Additive: ±1

|

Request A Quote

First of all, you can visit the production factory of the batching plant manufacturer. By visiting their factory, you

can learn how their workers work, how they produce the concrete batching

plant, how to correctly operate the machine and so on. Moreover, if you find a concrete batching and mixing

plant manufacturer that has its own workshop, this means that you will save the agency fees.

Then, you should learn the quality of machine produced by the concrete batch plant manufacturers. If you can

purchase a

high quality of concrete mixing plant, it will reduce your maintenance lately. Finally, you also should consider the

service attitude of the cement batching plant manufacturers. Good concrete plant manufacturers will provide you

with considerate and patient service at the whole trading process.

CBP60

install in Philippines

|

Model

|

CBP60

|

|

Capacity (m3/h)

|

60

|

|

Mixer

|

TCM1000

|

|

Aggregate Bin

|

ABM1600

|

|

Discharge Height (m)

|

4

|

|

Cycle Tine (s)

|

60

|

|

Weighing Accuracy(%)

|

Aggregate: ±2

|

|

Cement: ±1

|

|

Water: ±1

|

|

Additive: ±1

|

Request A Quote

CBP75

|

Model

|

CBP75

|

|

Capacity (m3/h)

|

75

|

|

Mixer

|

TCM1500

|

|

Aggregate Bin

|

ABM2400

|

|

Discharge Height (m)

|

3.8

|

|

Cycle Tine (s)

|

72

|

|

Weighing Accuracy(%)

|

Aggregate: ±2

|

|

Cement: ±1

|

|

Water: ±1

|

|

Additive: ±1

|

Request A Quote

Benefits you can get from a reputable manufacturer

What can you get from a good concrete batch mix plant manufacturer? There are a lot of benefits you can from this

concrete batching plant supplier, such as, high-quality product, reasonable design, competitive concrete batch plant

price, considerate and thoughtful service.

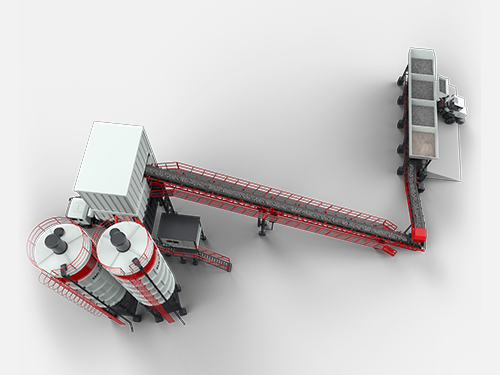

CBP90

belt conveyor type

|

Model

|

CBP90

|

|

Capacity (m3/h)

|

90

|

|

Mixer

|

TCM1500

|

|

Aggregate Bin

|

ABM2400

|

|

Discharge Height (m)

|

4

|

|

Cycle Tine (s)

|

60

|

|

Weighing Accuracy(%)

|

Aggregate: ±2

|

|

Cement: ±1

|

|

Water: ±1

|

|

Additive: ±1

|

Request A Quote

As we all know, concrete batch pant is not a small construction machinery. If there is something wrong with the

machine

during running, this will cause a lot of damage. Therefore, if you can get a good machine from your concrete

batching

plant manufacturer, long service life and low failure rate will reduce your loss.

In addition, the reputable batching plant manufacturers also will try their best to minimize your concrete batch plant cost.

Although your concrete plant cost is

affected

by many factors, they will help you design a good plan, a suitable type and model of plant, reasonable

transportation

route, etc.

At last, you also can enjoy a complete set of service from a credible batch mix plant manufacturer. A complete set

of

service includes pre-sale service, on-sale service and after-sale service. You can enjoy the consultation service,

installation service, training service, maintenance service and so on.

CBP120

|

Model

|

CBP120

|

|

Capacity (m3/h)

|

120

|

|

Mixer

|

TCM2000

|

|

Aggregate Bin

|

ABM3200

|

|

Discharge Height (m)

|

4

|

|

Cycle Tine (s)

|

60

|

|

Weighing Accuracy(%)

|

Aggregate: ±2

|

|

Cement: ±1

|

|

Water: ±1

|

|

Additive: ±1

|

Request A

Quote

CBP180

|

Model

|

CBP180

|

|

Capacity (m3/h)

|

180

|

|

Mixer

|

TCM3000

|

|

Aggregate Bin

|

ABM4800

|

|

Discharge Height (m)

|

4

|

|

Cycle Tine (s)

|

60

|

|

Weighing Accuracy(%)

|

Aggregate: ±2

|

|

Cement: ±1

|

|

Water: ±1

|

|

Additive: ±1

|

Request A

Quote

CBP240

|

Model

|

CBP240

|

|

Capacity (m3/h)

|

240

|

|

Mixer

|

TCM4000

|

|

Aggregate Bin

|

ABM6400

|

|

Discharge Height (m)

|

4

|

|

Cycle Tine (s)

|

60

|

|

Weighing Accuracy(%)

|

Aggregate: ±2

|

|

Cement: ±1

|

|

Water: ±1

|

|

Additive: ±1

|

Request A

Quote

Daswell Machinery - A reliable batch plant manufacturer Philippines

Daswell Machinery is a professional concrete batch plant manufacturer accumulating more

than 30

years production experience, located in Henan, China. As our business grows in Philippines, we have set up our

branch

office and warehouse in Philippines in recent years. So why choose us?

That is because we have advanced equipment

and

facility, skilled and experienced professionals, best competitive prices, stringent quality control, timely delivery

of

the consignments, easy payment options, etc.

Our production team will provide you with a variety of concrete plants, including stationary concrete batch plant, mobile batching plant, small

size

batch mix plant, ready mix concrete plant, wet mix concrete

batching

plant ad so on.

The production output of our concrete plant is varied, from 25m3/h to 240m3/h.

Whether

your project is large or small, you all pick up a right size of plant.

Many our concrete batching plants work in Philippines. If you are interested, you can visit them in local site. Of

course, our salesman will accompany with you all the time. You also listen to the review of our customers for our

machine and our service.

MCBP25 mobile type

|

Model

|

MCBP25

|

|

Capacity(m3/h)

|

25

|

|

Concrete mixer model

|

TCM500

|

|

Mixing power(kw)

|

18.5

|

|

Output per batch of mixer(m3)

|

0.5

|

|

Max. Aggregate Size

|

≤60/80

|

|

Aggregate bin(m3)

|

2×8

|

|

Walking speed(km/h)

|

20

|

|

Discharge height(m)

|

3.8

|

|

Total power(kw)

|

40

|

Request A

Quote

MCBP35

|

Model

|

MCBP35

|

|

Capacity(m3/h)

|

35

|

|

Concrete mixer model

|

TCM750

|

|

Mixing power(kw)

|

30

|

|

Output per batch of mixer(m3)

|

0.75

|

|

Max. Aggregate Size

|

≤60/80

|

|

Aggregate bin(m3)

|

2×8

|

|

Walking speed(km/h)

|

20

|

|

Discharge height(m)

|

3.8

|

|

Total power(kw)

|

55

|

Request A

Quote

MCBP50

|

Model

|

MCBP50

|

|

Capacity(m3/h)

|

50

|

|

Concrete mixer model

|

TCM1000

|

|

Mixing power(kw)

|

18.5×2

|

|

Output per batch of mixer(m3)

|

1

|

|

Max. Aggregate Size

|

≤60/80

|

|

Aggregate bin(m3)

|

4×8

|

|

Walking speed(km/h)

|

20

|

|

Discharge height(m)

|

4

|

|

Total power(kw)

|

75

|

Request A

Quote

What should you do before investing in a concrete plant

Before you buy a concrete cement plant, there are something you should do in order to start your business smoothly.

You should choose a place for your construction project. Moreover, you need to design this site reasonably.

Reasonable

design will reduce its floor area and save your original cost. Then you should get a right machine from a

trustworthy

batching plant supplier and install it on your site. Professional engineers from your concrete batch mix plant

manufacturer will guide you how to debug and operate the machine.

MCBP100

Daswell mobile plant in Philippines

Request A Quote

Next, you should hire several workers to operate the whole working process. Because of its high automatic degree of

our

concrete plants, several works can operate the whole process, which can save your labor cost. At last, you need to

debug

your machine and operate it.

No matter what question you have, please don’t hesitate to contact us. We will spare no efforts to help you solve it

in

time. Welcome to leave your message to us!

CBP25

CBP25

installation of cement silo

installation of cement silo

CBP35

CBP35

stationary type plant

stationary type plant

CBP50

CBP50

small size plant

small size plant

CBP60

CBP60

install in Philippines

install in Philippines

CBP75

CBP75

CBP90

CBP90

belt conveyor type

belt conveyor type

CBP120

CBP120

CBP180

CBP180

CBP240

CBP240

MCBP25 mobile type

MCBP25 mobile type

MCBP35

MCBP35

MCBP50

MCBP50

MCBP100

MCBP100

Daswell mobile plant in Philippines

Daswell mobile plant in Philippines