Concrete batching plant price can be affected by different factors, such as, types and models, transportation methods, installation and training service, etc. Maybe some of customers don’t learn the concrete batch mix plant, so they don’t know how to get a suitable machine with an affordable price. This means that you should learn this machine firstly when you want to purchase a cement batching plant. As a professional concrete plant manufacturer, if you consult us, our salesman will give you more professional advice. Here are some useful tips for you.

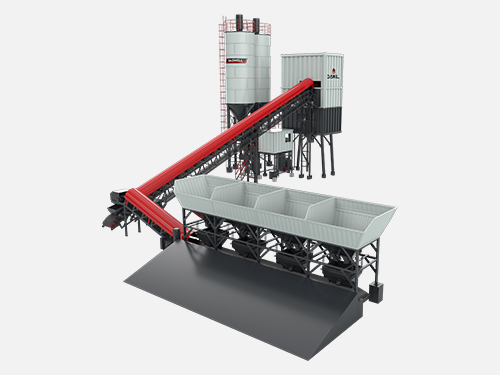

CBP25

CBP25

install the cement silo

install the cement silo

| Model | CBP25 |

| Capacity (m3/h) | 25 |

| Mixer | TCM500 |

| Aggregate Bin | ABM800 |

| Discharge Height (m) | 3.8 |

| Cycle Tine (s) | 72 |

| Weighing Accuracy(%) | Aggregate: ±2 |

| Cement: ±1 | |

| Water: ±1 | |

| Additive: ±1 |

Different types and models of concrete batch plants affect price

Our Daswell cement concrete batching plant has different types and models for our customers selection, including stationary type, mobile type, ready mix type, small portable type, etc. Moreover, these different types of cement concrete plant has different production volume. The concrete batch plants you choose are different, their prices are also different. Let me give you some examples.

CBP25 stationary type plant works in Philippines

CBP25 stationary type plant works in Philippines

CBP35

CBP35

| Model | CBP35 |

| Capacity (m3/h) | 35 |

| Mixer | TCM750 |

| Aggregate Bin | ABM1200 |

| Discharge Height (m) | 3.8 |

| Cycle Tine (s) | 72 |

| Weighing Accuracy(%) | Aggregate: ±2 |

| Cement: ±1 | |

| Water: ±1 | |

| Additive: ±1 |

CBP50

CBP50

| Model | CBP50 |

| Capacity (m3/h) | 50 |

| Mixer | TCM1000 |

| Aggregate Bin | ABM1600 |

| Discharge Height (m) | 3.8 |

| Cycle Tine (s) | 72 |

| Weighing Accuracy(%) | Aggregate: ±2 |

| Cement: ±1 | |

| Water: ±1 | |

| Additive: ±1 |

CBP75

CBP75

| Model | CBP75 |

| Capacity (m3/h) | 75 |

| Mixer | TCM1500 |

| Aggregate Bin | ABM2400 |

| Discharge Height (m) | 3.8 |

| Cycle Tine (s) | 72 |

| Weighing Accuracy(%) | Aggregate: ±2 |

| Cement: ±1 | |

| Water: ±1 | |

| Additive: ±1 |

Compare the stationary concrete mixing plant price and mobile concrete mixer plant price. Different from stationary concrete batching plant, mobile type plant installs its main parts on a trailer. So the operators can easily transport it from one site to another. Stationary concrete mixing plant is suitable for these projects that don’t need to transport. The stationary concrete plant price is slightly lower than mobile batching plant price. Then, let us see the large concrete batching plant price and small concrete batch mix plant price. As their name implied, the production volume of large size of concrete batching plant is larger than small size plant. Therefore, the large concrete mixing plant price is slightly higher than small concrete mixer plant price.

MCBP25 mobile type plant in Philippines

MCBP25 mobile type plant in Philippines

| Model | MCBP25 |

| Capacity(m3/h) | 25 |

| Concrete mixer model | TCM500 |

| Mixing power(kw) | 18.5 |

| Output per batch of mixer(m3) | 0.5 |

| Max. Aggregate Size | ≤60/80 |

| Aggregate bin(m3) | 2×8 |

| Walking speed(km/h) | 20 |

| Discharge height(m) | 3.8 |

| Total power(kw) | 40 |

To sum up, consider your purchase budget if you want to get a suitable price of concrete batching plant.

The price also depends on the different components

As we all know, the cement mixing plant is made of different components, such as, aggregate batching machine, concrete mixer machine, cement silo, screw conveyor, control system and so on. Because different customers have different requirements, our concrete batching plant will be equipped with different components depending on the customer’s requirement. Therefore, different component also will affect the concrete plant price.

TCM500 concrete mixer machine

TCM500 concrete mixer machine

ABM800 aggregate batching machine

ABM800 aggregate batching machine

cement silo

cement silo

control system

control system

The aggregate batching machine includes two bins, three pins, four bins, etc. Its models have ABM800, ABM1200, ABM1600,etc. You can choose the suitable model according to the kind of your raw materials and their weight. Our concrete batching plant adopts different control system, fully automatic type and semi automatic type. Fully automatic type concrete plant is controlled by the PLC and computer, which greatly reduces the labor intensity and labor cost. Of course, the fully automatic concrete batching plant price list is slightly higher than semi automatic concrete batch mix plant price.

MCBP35

MCBP35

| Model | MCBP35 |

| Capacity(m3/h) | 35 |

| Concrete mixer model | TCM750 |

| Mixing power(kw) | 30 |

| Output per batch of mixer(m3) | 0.75 |

| Max. Aggregate Size | ≤60/80 |

| Aggregate bin(m3) | 2×8 |

| Walking speed(km/h) | 20 |

| Discharge height(m) | 3.8 |

| Total power(kw) | 55 |

MCBP50

MCBP50

| Model | MCBP50 |

| Capacity(m3/h) | 50 |

| Concrete mixer model | TCM1000 |

| Mixing power(kw) | 18.5×2 |

| Output per batch of mixer(m3) | 1 |

| Max. Aggregate Size | ≤60/80 |

| Aggregate bin(m3) | 4×8 |

| Walking speed(km/h) | 20 |

| Discharge height(m) | 4 |

| Total power(kw) | 75 |

MCBP75

MCBP75

| Model | MCBP75 |

| Capacity(m3/h) | 75 |

| Concrete mixer model | TCM1500 |

| Mixing power(kw) | 30×2 |

| Output per batch of mixer(m3) | 1.5 |

| Max. Aggregate Size | ≤60/80 |

| Aggregate bin(m3) | 4×8 |

| Walking speed(km/h) | 20 |

| Discharge height(m) | 4 |

| Total power(kw) | 105 |

Other related concrete batch plant cost

When you plan to purchase a cement mixer plant for sale, besides concrete mixer plant price, you also need to think about the other related batching plant cost, such as, the construction site cost, transportation cost, maintenance cost, labor cost, etc. Therefore, you should take these factors into consideration.

Before starting a cement batching plant business, you should get your own construction site and reasonably plan it. Rational design will reduce your construction site area and save your total concrete plant cost. In addition, choosing a suitable transportation methods will also help you reduce your total concrete mixing plant cost.

CBP90 belt conveyor type plant in

Philippines

CBP90 belt conveyor type plant in

Philippines

| Model | CBP90 |

| Capacity (m3/h) | 90 |

| Mixer | TCM1500 |

| Aggregate Bin | ABM2400 |

| Discharge Height (m) | 4 |

| Cycle Tine (s) | 60 |

| Weighing Accuracy(%) | Aggregate: ±2 |

| Cement: ±1 | |

| Water: ±1 | |

| Additive: ±1 |

What’s more, you also need to look for a credible concrete batching plant manufacturer. They will provide you with sincere service, which also minimizes your concrete batching plant price. If you still have any question, welcome to contact us to get more detailed information.

Select a trustworthy and reputable manufacturer

Why should you choose a trustworthy and reputable concrete batch plant manufacturer when you buy this product? That is because you can get some benefits from it. A reputable concrete plant manufacturer must receive high praise from their customers because of their good machine and favorable concrete batch plant cost.

Moreover, choose a trustworthy concrete batch plant supplier, you can enjoy their considerate service, such as, consultation service, installation and debugging service, training service, maintenance and repairment service, etc. High-quality concrete mixing plant and regular maintenance will effectively reduce the failure rate and concrete batching plant price.

CBP60

CBP60

work in Philippines

work in Philippines

| Model | CBP60 |

| Capacity (m3/h) | 60 |

| Mixer | TCM1000 |

| Aggregate Bin | ABM1600 |

| Discharge Height (m) | 4 |

| Cycle Tine (s) | 60 |

| Weighing Accuracy(%) | Aggregate: ±2 |

| Cement: ±1 | |

| Water: ±1 | |

| Additive: ±1 |

CBP120

CBP120

| Model | CBP120 |

| Capacity (m3/h) | 120 |

| Mixer | TCM2000 |

| Aggregate Bin | ABM3200 |

| Discharge Height (m) | 4 |

| Cycle Tine (s) | 60 |

| Weighing Accuracy(%) | Aggregate: ±2 |

| Cement: ±1 | |

| Water: ±1 | |

| Additive: ±1 |

CBP180

CBP180

| Model | CBP180 |

| Capacity (m3/h) | 180 |

| Mixer | TCM3000 |

| Aggregate Bin | ABM4800 |

| Discharge Height (m) | 4 |

| Cycle Tine (s) | 60 |

| Weighing Accuracy(%) | Aggregate: ±2 |

| Cement: ±1 | |

| Water: ±1 | |

| Additive: ±1 |

Like our Daswell Machinery, we are a professional concrete plant supplier in Philippines. And now, we have our branch office and warehouse there. If you are in Philippines, and if you want to get a satisfied machine with a favorable batching plant cost, please don’t hesitate to choose our company! We will provide you with the best machine and price.